Multi-Pin vs. Single-Pin Automotive Connectors

Choosing the right connector for your automotive electrical system can make or break the success of your project. Engineers and technicians face this critical decision daily, and the wrong choice leads to system failures, increased costs, and frustrated customers. Understanding the fundamental differences between multi-pin and single-pin automotive connectors helps you make informed decisions that ensure reliable performance and optimal functionality.

Single-Pin Connectors

Single-pin connectors represent the simplest form of electrical connection in automotive applications. These connectors establish one electrical path between two components, making them straightforward to install and troubleshoot. The design features a male terminal that inserts into a female housing, forming a secure electrical connection.

These connectors excel in applications requiring individual wire management. When you need to connect a single wire to a component or create a junction point in your wiring harness, single-pin connectors provide the most direct solution. Their modular nature allows technicians to customize connections based on specific requirements without committing to predetermined pin configurations.

Single-pin connectors offer exceptional flexibility during the design phase. You can position them anywhere along a wire run, and their compact size makes them ideal for tight spaces where larger connectors won’t fit. The ability to use different connector types for different circuits within the same system provides design freedom that multi-pin alternatives cannot match.

Multi-Pin Connectors

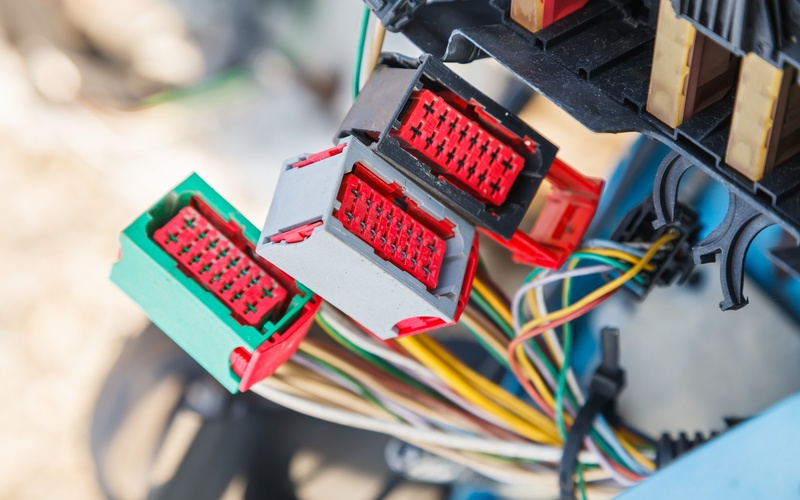

Multi-pin connectors consolidate multiple electrical connections into a single housing unit. This consolidated design creates a centralized connection point, simplifying wire management and reducing the overall number of connection points in a system.

The housing design of multi-pin connectors provides superior protection for individual circuits. Each pin sits within a dedicated cavity, preventing cross-connection errors and providing mechanical support for the terminals. This design approach significantly reduces the risk of incorrect connections during assembly or service procedures.

Multi-pin connectors incorporate keying features that prevent incorrect mating. These mechanical safeguards ensure that connectors can only be connected in the correct orientation, eliminating the possibility of reversed connections that could damage sensitive electronic components. The keying system also prevents technicians from connecting the wrong connectors together during assembly or repair operations.

Installation and Assembly Considerations

Single-pin connectors require individual attention during installation, which can increase assembly time when dealing with multiple circuits. Each connector must be positioned, secured, and tested individually. This process becomes time-consuming when working with complex systems that require numerous individual connections.

However, single-pin connectors provide excellent serviceability. Technicians can access and replace individual connections without disturbing other circuits. This capability proves invaluable during diagnostic procedures and repair operations where isolating specific circuits becomes necessary.

Multi-pin connectors streamline the assembly process by consolidating multiple connections into a single mating operation. One connector engagement secures all circuits simultaneously, reducing assembly time and eliminating the possibility of forgotten connections. This efficiency becomes particularly valuable in production environments where assembly speed has a direct impact on costs.

The trade-off comes during service operations. Multi-pin connectors require the disconnection of all circuits to access individual pins. This limitation can complicate diagnostic procedures and force technicians to disconnect functioning circuits to service unrelated problems.

Electrical Performance Characteristics

Connectors exhibit different electrical performance characteristics that impact system design decisions. Single-pin connectors typically offer superior current-carrying capacity for their size because the entire connector is dedicated to a single circuit. The larger contact area and shorter current path result in lower resistance and better thermal performance.

Multi-pin connectors must balance current capacity across multiple circuits while adhering to size constraints. Individual pins in multi-pin connectors often have lower current ratings compared to equivalent single-pin alternatives. However, the consolidated design can improve overall system performance by reducing the number of connection points and potential failure modes.

Contact resistance varies between connector types, depending on their design and manufacturing quality. Single-pin connectors often achieve lower contact resistance because designers can optimize the contact geometry for maximum performance. Multi-pin connectors must compromise on contact design to accommodate multiple pins within space limitations.

Environmental Protection and Sealing

Environmental sealing presents different challenges for each connector type. Single-pin connectors require individual sealing solutions, which can create multiple potential leak paths in harsh environments. Each connector represents a separate sealing challenge that must be addressed during system design.

Multi-pin connectors offer centralized sealing, providing superior environmental protection. A single seal design protects all circuits simultaneously, reducing the number of potential failure points. Advanced multi-pin automotive connectors feature multiple sealing barriers, providing redundant protection against moisture, dust, and chemical contamination.

The sealing effectiveness depends heavily on proper installation and maintenance. Single-pin connectors facilitate easier inspection and maintenance of individual seals, whereas multi-pin connectors necessitate complete disconnection for seal inspection and replacement.

Cost Analysis and Economic Factors

Initial cost considerations favor single-pin connectors for simple applications. The lower per-unit cost makes single-pin connectors attractive for basic connections where advanced features aren’t required. However, the total system cost includes installation labor, which can favor multi-pin solutions in complex applications.

Multi-pin connectors carry higher initial costs but provide economic advantages in complex systems. The reduced installation time and improved reliability can offset the higher connector costs through reduced labor expenses and improved long-term performance.

Inventory management also impacts the total cost of ownership. Single-pin connectors require maintaining stock of individual components, while multi-pin connectors consolidate inventory requirements. The reduced part number count can simplify procurement and reduce inventory carrying costs.

Application-Specific Selection Criteria

Simple circuits with minimal complexity benefit from single-pin connector solutions. Applications such as individual sensor connections, simple switch circuits, and basic lighting systems work well with single-pin approaches. The straightforward nature of these applications doesn’t justify the additional complexity and cost of multi-pin solutions.

Complex systems with multiple related circuits require careful evaluation of both options. Engine management systems, body control modules, and advanced driver assistance systems often benefit from the consolidation of multi-pin connectors. The related nature of these circuits and the need for organized wire management typically favor multi-pin solutions.

Critical systems that require maximum reliability may benefit from single-pin connector redundancy. The ability to isolate individual circuits and provide dedicated connections for each critical function can improve overall system reliability in mission-critical applications.

Making the Right Choice for Your Application

Multi-pin and single-pin automotive connectors each serve specific purposes in modern vehicle electrical systems. Your selection depends on system complexity, reliability requirements, environmental conditions, and economic considerations. Single-pin connectors excel in simple, individual circuit applications where flexibility and serviceability take priority. Multi-pin connectors provide advantages in complex systems where consolidation, organization, and assembly efficiency drive design decisions. The right connector choice today prevents costly redesigns and service complications tomorrow.

You must login to post comments.