The Role of Micro-Connectors in Modern Vehicle Design

Today’s vehicles pack more technology into tighter spaces than ever before. From advanced driver assistance systems to high-resolution infotainment displays, every feature relies on reliable electrical connections. That’s where micro-connectors step in.

If you’re sourcing connectors for a repair or redesign, now’s the time to understand how these compact components shape performance and reliability across modern platforms. A closer look at the role of micro-connectors in modern vehicle design reveals why they’ve become a core part of automotive engineering. Learn how these critical components keep vehicles running in a wide range of conditions.

Smaller Vehicles, Greater Electrical Demand

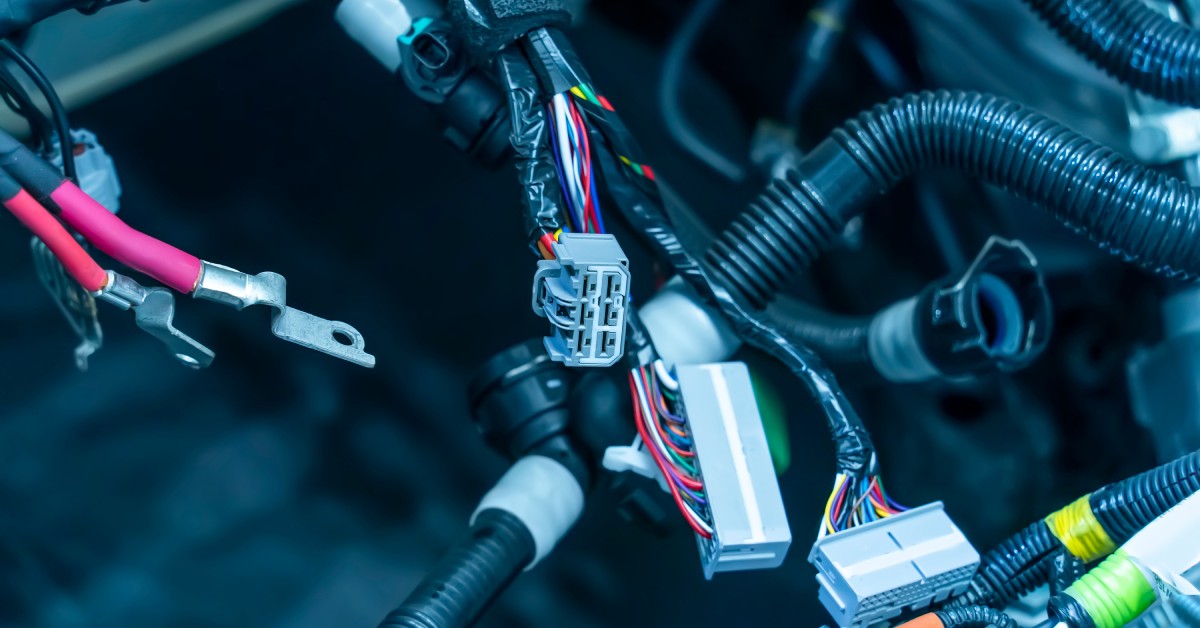

Open the hood of a late-model vehicle and you’ll notice something right away: space is limited. Engine bays look cleaner and more compact, yet they house more sensors, modules, and wiring than vehicles from a decade ago. Carmakers push for lighter builds and tighter layouts to improve fuel economy and range.

Micro-connectors support that shift. Their compact footprint allows engineers to route wiring through narrow channels and crowded modules. Instead of bulky harness junctions, technicians now work with small, high-density connectors that fit where traditional designs never could.

This transition affects repair shops as well. A replacement connector must match tight tolerances and fit within confined assemblies. Access to the right micro-connector can keep a repair on track without major disassembly.

High-Density Electronics Require Precision

Modern vehicles rely on dozens of control units that communicate across complex networks. Camera systems, radar modules, throttle control, transmission control, and battery management all depend on stable signal transmission. Micro-connectors support these systems through high pin counts in compact housings. You can buy 6-wire connectors that fit many pins into one, compact component.

A backup camera harness provides a good example. The connector may carry power, ground, and multiple signal lines within a small sealed body. That design reduces space use without sacrificing performance. Precision terminal alignment and secure locking tabs prevent signal loss and intermittent faults.

For mechanics and collision repair centers, this means connector quality cannot fall short. A poorly fitted terminal or weak latch can trigger warning lights, sensor failures, or communication codes.

Weight Reduction and Fuel Efficiency

Automakers track vehicle weight closely. Even small reductions contribute to improved fuel economy and extended EV range. Micro-connectors help reduce overall harness bulk and material usage.

Smaller housings require less plastic, and compact terminals use less metal. Across an entire vehicle platform, these reductions add up. In electric vehicles, where battery efficiency remains a top concern, lightweight wiring solutions support longer driving distance per charge.

Technicians may not think about connector weight during a repair, yet the original engineering decision impacts the entire vehicle system. Using correct replacement connectors preserves that balance.

Compact size does not mean reduced durability. Many micro-connectors feature sealed designs that protect terminals from moisture, road salt, and debris. Underhood environments expose components to vibration and temperature swings, so connector integrity matters.

Consider a sensor mounted near a wheel well. Road spray and grit pose constant threats. A sealed micro-connector keeps contamination away from terminals, which protects signal accuracy and prevents corrosion.

When a connector fails in these areas, replacement must match the original sealing capability. A non-sealed substitute may fit physically but leave the system vulnerable to future faults.

Electric and Hybrid Vehicle Integration

Electric and hybrid vehicles introduce even greater electrical complexity. Battery packs, inverters, onboard chargers, and thermal management systems all rely on specialized connectors. Micro-connectors handle low-voltage communication circuits within these high-voltage environments.

Inside a battery management system, compact connectors link temperature sensors and monitoring circuits. Space within battery enclosures remains limited, so compact designs allow efficient routing without crowding.

For repair professionals, sourcing exact-fit connectors becomes critical. Many of these parts do not appear in traditional auto parts inventories. Access to specialized automotive connectors keeps repair timelines manageable.

Supporting Advanced Driver Assistance Systems

Advanced driver assistance systems rely on precise communication between cameras, radar, and control modules. These components mount in tight areas such as mirrors, bumpers, and windshields. Micro-connectors allow secure connections within limited space.

A forward-facing camera behind the windshield uses compact connectors that fit inside slim housings. These connectors maintain stable data transfer, which supports lane departure alerts and collision warning systems.

Shops that perform ADAS repairs or recalibration need reliable connector sources. A damaged micro-connector can halt system operation, leading to dashboard alerts and compromised safety features.

Repair Challenges and Replacement Accuracy

Micro-connectors bring advantages, yet they also demand careful handling. Their small terminals require precise crimp tools and proper pin alignment. A slight misalignment can lead to poor contact or intermittent faults.

Collision repairs highlight this challenge. During front-end damage, harnesses near headlights and sensors may suffer connector damage. Replacing only the damaged connector, instead of the entire harness, saves time and cost. That solution depends on locating the correct housing and terminal type.

Thermal Management and Compact Connector Design

Heat management plays a larger role in modern vehicle platforms than many realize. Turbocharged engines, hybrid drivetrains, and dense electronic packaging create higher localized temperatures. Micro-connectors must operate reliably in these conditions without terminal distortion or housing degradation.

Materials used in these connectors support stable electrical contact across wide temperature ranges. Engineers select specialized plastics and plating finishes that resist heat-related expansion and contraction. That stability protects signal continuity inside engine compartments and battery enclosures.

For repair shops, matching the correct connector material matters just as much as matching the shape. A lower-grade substitute may fit but fail under sustained thermal stress. Correct replacement protects system reliability long after the vehicle leaves the bay.

Why You Need to Know The Role of Micro-Connectors

Understanding the role of micro-connectors in modern vehicle design helps shops adapt to evolving vehicle platforms. Electrical systems grow more compact and more complex each model year. Reliable repairs depend on precise connector selection, correct sealing, and secure terminal fit.

Micro-connectors influence system stability, sensor accuracy, and communication across modules. A small plastic housing may appear minor, yet it supports systems that drivers rely on every day. Proper replacement protects vehicle performance and prevents repeat visits for electrical faults.

As vehicles continue to evolve, connector design will follow suit. Compact, sealed, and high-density solutions will appear in more locations across every platform.

If you run a shop that handles late-model diagnostics, collision repair, or electrical troubleshooting, keep micro-connectors on your radar. You should source parts that match factory specifications and support long-term durability. Partner with suppliers who understand automotive connector applications and provide access to components you won’t find at typical auto parts counters. The right connector keeps your repairs solid and your customers confident on the road.

You must login to post comments.