How Connector Seals Protect Against Road Debris

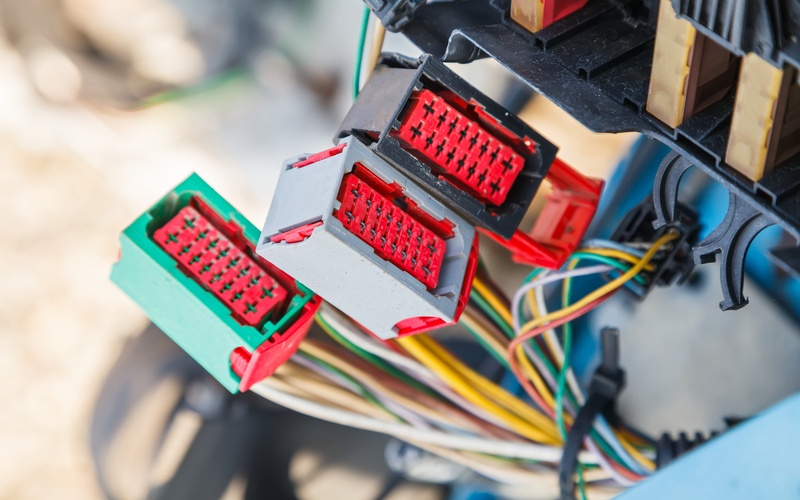

When you’re working on a vehicle that’s seen a few winters, you’ve seen what road debris can do. Salt crusted around housings. Grit packed into cavities. Moisture that creeps into places it has no business being. If you want connectors that last longer and hold up under harsh road conditions, it’s worth taking a closer look at how seals do their job. Let’s break down how connector seals protect against road debris.

The Real Threat: What Road Debris Does to Connectors

Automotive electrical systems sit in tough environments. Connectors near wheel wells, bumpers, and undercarriages face constant exposure to dirt, sand, water spray, and road salt. Add vibration and heat cycles, and you’ve got a recipe for corrosion and intermittent faults.

Seals act as the barrier between that environment and the delicate metal terminals inside. Without them, even a high-quality connector can fail long before its time.

Road debris comes in many forms. Fine dust can work its way into tiny gaps. Saltwater spray can cling to housings and seep through small openings. Gravel can chip plastic and create entry points for moisture.

Once contaminants reach the terminals, corrosion starts to form. Corrosion raises electrical resistance, which leads to voltage drops, signal loss, and sensor errors. In high-current circuits, that additional resistance can generate heat. Over time, it’s common for terminals to pit, discolor, or lose tension.

Shops see the result as mystery electrical issues. A vehicle may run fine one day and throw a fault code the next. When connectors lack proper sealing, the problem rarely stays isolated to one component.

Where Seals Fit into the Connector Design

Connector seals sit at strategic points within the housing. Some wrap around individual wires at the rear of the connector. Others sit between mating halves, creating a tight interface when the connector locks into place. Together, they create multiple layers of protection.

Rear wire seals grip the insulation of each wire. That tight fit blocks moisture and dirt from entering through the back of the connector. Interface seals compress when the connector mates, which forms a gasket-like barrier between the two halves.

This layered approach keeps debris out from more than one direction. Even if grime coats the exterior, the interior remains protected. That separation allows terminals to stay clean and conductive.

Materials That Stand Up to Harsh Conditions

Most connector seals use elastomer materials such as silicone or specialized rubber compounds. These materials stay flexible across wide temperature ranges. In cold climates, they resist cracking. In high-heat zones near engines, they maintain their shape and compression.

Flexibility plays a large role in performance. A seal that can compress and rebound creates a tighter fit. That tight interface blocks water and dust from slipping past the barrier.

Chemical resistance also matters. Road salt, oil mist, and fuel vapors can degrade low-grade materials. Automotive-grade seals resist those chemicals, which extends connector life in demanding environments.

Compression: The Secret Behind a Tight Seal

Seals work best when properly compressed. When the connector locks, the housing presses the seal into place. That pressure fills microscopic gaps between plastic surfaces.

If compression falls short, small channels remain. Water and fine particles can travel through those channels over time. On the other hand, too much compression can deform the seal and reduce long-term performance.

That balance comes from precise connector design. Manufacturers calculate how much force the latch applies and how much the seal should compress. When you source quality connectors built for automotive use, that engineering shows up in the field as fewer failures.

Protection Against Vibration and Movement

Vehicles don’t sit still. Engines vibrate, suspensions flex, and harnesses shift slightly with road movement. Over thousands of miles, that motion will stress connectors.

Seals add stability in addition to blocking debris. A properly fitted rear seal supports the wire at the entry point. That support reduces strain on the terminal crimp.

Interface seals also help dampen small movements between mating halves. With less micro-motion, terminals maintain solid contact. That stability reduces wear and helps maintain consistent electrical performance.

Wheel Speed Sensors

Take wheel speed sensors as an example. These connectors live near brake components and wheel hubs. They face water spray, brake dust, salt, and gravel on a daily basis.

A connector without a solid seal may let moisture creep inside. Corrosion at the terminal can distort the sensor signal. The driver may see an ABS warning light that seems to appear out of nowhere.

With a well-sealed connector, the internal terminals stay clean despite the harsh surroundings. The sensor continues to send accurate data and the repair shop avoids a comeback tied to moisture intrusion.

IP Ratings and What They Mean for Automotive Connectors

Understanding how connector seals protect against road debris helps you make better decisions during repairs. Many sealed connectors carry an IP rating, which indicates resistance to dust and water. An IP67-rated connector, for example, resists dust ingress and can handle temporary water immersion under defined conditions.

These ratings give mechanics and installers a reference point. A higher rating reflects better protection against contaminants. That extra protection proves valuable in underbody and exterior applications.

For shops that deal with collision repair or harness replacement, matching or exceeding the original connector’s protection level supports long-term reliability. A connector that meets the environment reduces the risk of repeat electrical faults.

Why Quality Sourcing Matters

Not all connectors offer the same level of sealing performance. Low-cost options may use inferior materials or loose tolerances. Those shortcuts can show up months later as corrosion or intermittent electrical issues.

Connector Experts specializes in automotive connectors, such as 5-pin plug connectors. Our extensive inventory of connectors supports repair shops that need the right fit for specific makes and models. When a harness repair calls for a sealed connector that matches factory performance, quality sourcing pays off.

A properly sealed connector protects terminals from the start. That protection helps maintain low resistance and stable signals. Over time, that reliability builds trust with customers.

Long-Term Reliability Starts at the Connector

Electrical systems grow more complex every model year. Advanced driver assistance systems, emissions controls, and infotainment modules all depend on clean, stable connections. A small amount of debris at a single connector can disrupt an entire circuit.

Seals act as the first line of defense. They block dirt, moisture, and salt before corrosion takes hold. In harsh climates, that barrier supports longer service life for sensors, modules, and actuators.

If your next repair involves a connector exposed to the elements, take a close look at the seal design before you install it. Choosing a properly sealed automotive connector supports long-term reliability and protects the circuit from dirt, salt, and moisture down the road

You must login to post comments.