Guide to Automotive Electrical Connector Standards

The automotive industry demands precision, reliability, and safety in every component. Electrical connectors serve as the backbone of modern vehicle systems, linking everything from engine management to infotainment networks. Understanding automotive electrical connector standards isn’t optional—it’s essential for anyone working with vehicle electronics.

This comprehensive guide to automotive electrical connector standards covers the critical specifications, testing requirements, and application guidelines you need to ensure proper connector selection and installation. Whether you’re designing new systems or maintaining existing ones, mastering these standards will elevate your work and prevent costly failures.

Understanding Automotive Connector Classifications

Automotive electrical connectors are categorized based on their intended use and level of environmental exposure. Primary classifications include sealed and unsealed connectors, each designed for specific applications within the vehicle architecture.

Sealed connectors feature weatherproof housings with gaskets or seals that prevent moisture, dust, and contaminants from entering the connection point. These connectors are mandatory for engine bay applications, exterior lighting, and any system exposed to harsh environmental conditions. The sealing mechanism typically involves rubber gaskets, O-rings, or molded seals that create a barrier against the ingress of fluids or gases.

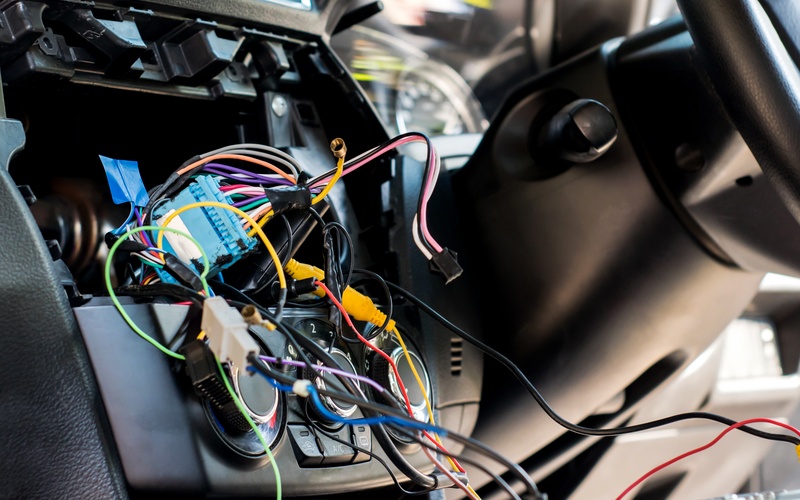

Unsealed connectors lack environmental protection and are reserved for interior applications where exposure to moisture and contaminants is minimal. These connectors are commonly found in dashboard electronics, interior lighting, and passenger compartment systems, where the controlled environment eliminates the need for additional sealing.

Temperature ratings represent another crucial classification factor. Connectors must withstand the extreme temperature variations encountered in automotive environments, from sub-zero cold starts to engine bay heat exposure.

SAE J1928 Standard Requirements

The Society of Automotive Engineers (SAE) J1928 standard establishes the fundamental requirements for automotive electrical connectors. This standard defines dimensional specifications, material requirements, and performance criteria that ensure consistent connector quality across the industry.

J1928 mandates specific contact resistance values, typically requiring initial contact resistance below 2.5 milliohms for power applications and 5 milliohms for signal circuits. These resistance values must remain stable throughout the connector’s operational life, even after exposure to temperature cycling, vibration, and corrosion testing.

Material specifications under J1928 address both the connector housing and contact elements. Housing materials must demonstrate adequate strength, chemical resistance, and dimensional stability across the required temperature range. Contact materials typically consist of copper alloys with protective plating to prevent corrosion and maintain conductivity.

The standard also establishes insertion and withdrawal force requirements, ensuring that connectors can be properly mated and separated without damage. These force specifications prevent accidental disconnection while allowing for reasonable service access when necessary.

ISO 8092 Compliance Framework

The International Organization for Standardization (ISO) 8092 standard provides a global framework for automotive connector specifications. This standard emphasizes dimensional accuracy, material compatibility, and testing protocols that ensure worldwide interchangeability of connectors.

ISO 8092 defines precise dimensional tolerances for connector bodies, contact positions, and mating interfaces. These tolerances ensure that connectors from different manufacturers will mate properly and maintain reliable electrical connections throughout their service life.

The standard requires comprehensive material testing, including thermal aging, chemical resistance, and mechanical stress evaluation. Materials must demonstrate consistent performance across the specified temperature range without degradation of electrical or mechanical properties.

Testing protocols under ISO 8092 include accelerated aging tests, thermal cycling, vibration testing, and evaluation of corrosion resistance. These tests simulate real-world automotive conditions and verify that connectors will perform reliably throughout the vehicle’s expected service life.

USCAR Standards Implementation

The United States Council for Automotive Research (USCAR) has developed specific standards for automotive electrical connectors used in North American vehicles. These standards address unique regional requirements and regulatory compliance needs.

USCAR-2 establishes performance requirements for automotive electrical connectors, including current carrying capacity, voltage drop limitations, and durability testing protocols. The standard requires connectors to maintain specified performance levels after exposure to salt spray, temperature cycling, and mechanical stress.

Contact plating specifications under USCAR standards typically require tin, gold, or silver plating to ensure reliable electrical connections. The plating thickness and quality must meet strict requirements to prevent corrosion and maintain conductivity throughout the connector’s service life.

USCAR standards also address electromagnetic compatibility (EMC) requirements, ensuring that connectors do not contribute to electrical interference or susceptibility issues. This includes specifications for connector shielding, grounding, and maintaining signal integrity.

Terminal and Contact Specifications

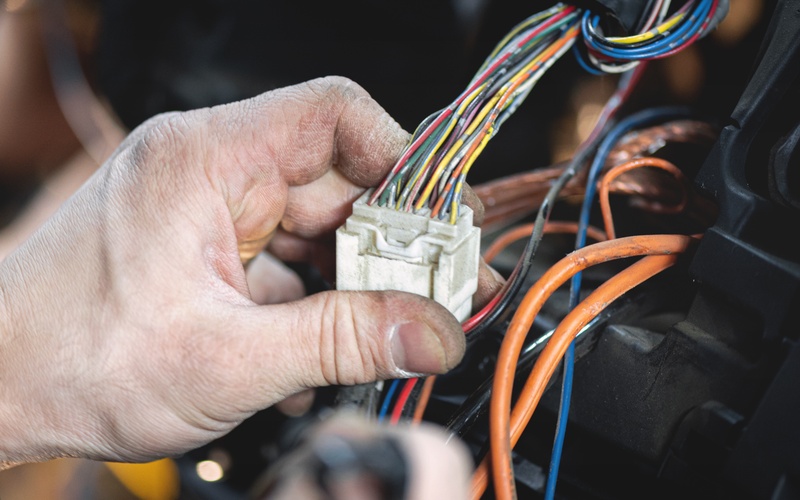

Automotive connector terminals and contacts must meet rigorous specifications to ensure reliable electrical connections. Contact design parameters include material selection, plating requirements, and dimensional accuracy.

Contact materials typically consist of copper alloys chosen for their conductivity, strength, and corrosion resistance. The base material must maintain its properties across the required temperature range while providing adequate spring force for reliable mating.

Plating specifications vary based on the application and environmental exposure. Tin plating is commonly used for general applications, while gold plating may be required for low-voltage signal circuits or critical connections. Silver plating offers excellent conductivity for high-current applications.

Terminal crimping specifications ensure that proper mechanical and electrical connections are made between the wire and the terminal. Crimp quality affects both the electrical performance and mechanical reliability of the connection. Proper crimping tools and techniques are essential for achieving specification compliance.

Wire Gauge and Current Capacity

Automotive electrical systems require careful matching of the wire gauge to current capacity and connector ratings. Standard wire gauges range from 24 AWG for low-current signal circuits to 4 AWG or larger for high-current power applications.

Current capacity calculations must consider ambient temperature, conductor material, and insulation rating. Automotive applications often require derating factors to account for elevated temperatures and bundling effects that reduce current-carrying capacity.

Connector contact ratings must match or exceed the wire current’s capacity to prevent overheating and connection failure. A 9-pin connector pigtail assembly, for example, must have individual contacts rated for the specific current requirements of each circuit.

Considering voltage drop is critical in automotive applications where system voltages are relatively low. Connector resistance, combined with wire resistance, can significantly impact system performance if not properly managed.

Environmental Testing Requirements

Automotive connectors must withstand harsh environmental conditions throughout their service life. Testing protocols simulate these conditions to verify the performance and reliability of the connector.

Temperature cycling tests subject connectors to repeated heating and cooling cycles that simulate the real-world thermal stress they encounter. These tests verify that connectors maintain electrical and mechanical performance across temperature extremes without degradation.

Vibration testing simulates the mechanical stress encountered in automotive applications. Connectors must maintain electrical continuity and mechanical integrity when subjected to specified vibration profiles that replicate vehicle operating conditions.

Corrosion resistance testing evaluates the performance of connectors when exposed to salt spray, humidity, and other corrosive environments. This testing ensures that connectors will maintain their performance throughout the vehicle’s expected service life.

Application-Specific Considerations

Different automotive systems require specialized connector considerations based on their unique operating requirements. Engine management systems require high-reliability connectors that can withstand extreme temperatures and vibration.

Powertrain applications require connectors with high current capacity and excellent thermal management. These connectors must maintain performance under continuous high-current operation while resisting degradation from heat and vibration.

Safety-critical systems such as airbag deployment circuits require ultra-reliable connectors with redundant contact systems and enhanced environmental protection. These applications may require gold-plated contacts and specialized testing protocols.

Mastering Connector Standards for Success

Understanding and implementing automotive electrical connector standards is fundamental to creating reliable vehicle electrical systems. This guide to automotive electrical connector standards has covered the essential specifications and requirements that govern connector selection and application. By following these standards and implementing proper installation practices, you can ensure that your automotive electrical systems deliver the reliability and performance that modern vehicles demand.

You must login to post comments.