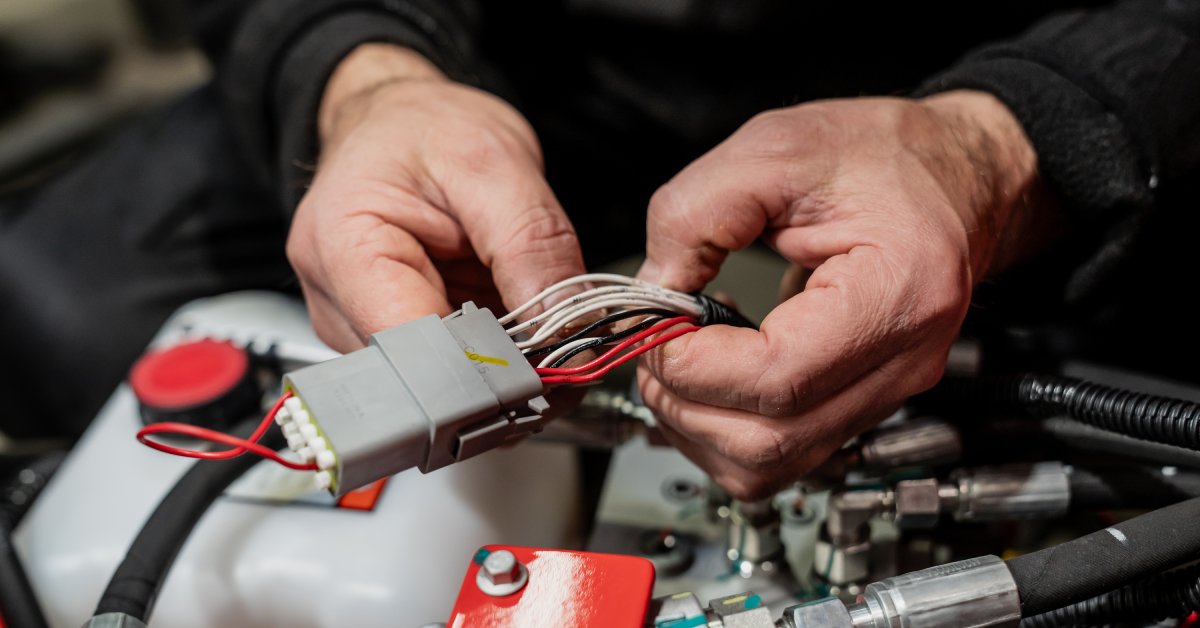

What Type of Sealing To Use for Vehicle Wiring Connections?

When working with vehicle wiring connections, reliability, protection, and longevity are non-negotiable. Poor sealing can lead to corrosion, electrical failures, and safety risks. With a range of sealing options available, each suited to different applications, understanding their proper use is crucial for professionals working with vehicle wiring systems.

This blog explains the type of sealing to use for vehicle wiring connections, ensuring your work meets the highest standards of performance and durability. By the end of this post, you’ll know how to select the ideal sealing solution for your project.

The Importance of Sealing in Vehicle Wiring

Exposure to water, dirt, or extreme temperatures can hinder the performance of vehicle wiring connections. Sealing enhances the durability of these connections by providing protection against environmental hazards, making the wiring functional under harsh conditions.

Proper sealing safeguards connections against short circuits and corrosion, while maintaining the integrity of vehicle systems. Failing to take this critical step could result in unnecessary repairs and costs, potentially compromising the system’s safety and efficiency.

Remember, your choice of sealing isn’t just about protection. It’s about selecting the right solution for the specific wiring environment and working conditions, too.

Heat Shrink Tubing

One highly recommended solution is heat shrink tubing. This type of sealing is widely used in vehicle wiring connections due to its durability and ease of installation. Heat shrink tubing is placed over the wiring connection and shrinks when exposed to heat to form a tight seal.

This sealing method is particularly effective for environments where connectors, such as 6-pin connectors, might encounter water, oils, and other contaminants. Its snug fit and flexibility allow it to conform to various connection sizes and shapes.

However, it is important to ensure proper application. Make sure the tubing fully covers the wiring connection. Use a consistent heat source to shrink it evenly. Correctly installed heat shrink tubing can provide excellent insulation and environmental protection.

Adhesive-Lined Heat Shrink Tubing

For a more advanced level of sealing, adhesive-lined heat shrink tubing can be a better option. This type includes an inner adhesive layer that melts during the shrinking process, creating additional protection.

Adhesive-lined tubing reliably blocks out moisture and contaminants. The inner adhesive layer bonds with the wiring surfaces, further enhancing durability. Therefore, it’s an ideal choice for vehicles in extreme conditions or areas exposed to water.

It’s important to note that this type of sealing may require greater precision during application. Be sure to use the correct tubing size because the adhesive must fully bond with the wiring for maximum effectiveness.

Silicone Sealants

Silicone sealants are another reliable option for sealing vehicle wiring connections. Known for their flexibility and water resistance, silicone sealants are ideal for insulating electrical connections that require additional reinforcement.

This sealing option is particularly useful for irregularly shaped or hard-to-reach connections where heat shrink tubing may not fit perfectly. Silicone ensures complete coverage by adapting to the unique contours of the connection.

Clean the surface of contaminants that could interfere with adhesion. Apply an even layer over the connection for full coverage. Allow adequate curing time to ensure the sealant sets properly. Once cured, the silicone will provide dependable protection against moisture and environmental stress.

Electrical Tape

While not as robust as other sealing methods, electrical tape remains a common choice for less demanding situations. It is easy to use, affordable, and widely available.

Electrical tape is effective in temporary or low-exposure environments where intense protection isn’t required. However, for vehicle wiring connections that experience significant moisture, temperature fluctuations, or contaminants, this option may not provide the long-term durability needed.

To use electrical tape as a sealant, wrap it tightly around the wiring connection. Overlap the layers slightly to reinforce the seal. Be cautious of stretches or gaps that could compromise protection.

Plastic and Rubber Grommets

Another sealing option for vehicle wiring connections is the use of plastic or rubber grommets. In engine compartments or wiring harnesses, these protect wiring passing through sharp or irregular surfaces.

Rubber grommets, in particular, offer superior flexibility and resistance to wear and tear, creating a secure seal that protects wires from abrasion and environmental hazards.

When using plastic or rubber grommets, ensure that the grommet size matches the opening and wiring being sealed. Improper sizing can leave gaps that expose wires to potential damage. Well-installed grommets effectively create a protective barrier while maintaining wiring integrity.

What To Use for Vehicle Wiring Connections in High-Risk Areas

High-risk areas, such as engine bays and undercarriage wiring, demand rigorous sealing due to constant exposure to vibration, heat, water, and debris. For optimal protection, the best solutions are adhesive-lined heat shrink tubing or a combination of silicone sealants and rubber grommets.

The added adhesive in heat shrink tubing provides superior moisture resistance, while silicone sealants further reinforce irregular connections. Rubber grommets help maintain wire integrity when threading cables through mounting holes, preventing fraying or wear caused by vibrations.

These methods ensure that vehicle wiring connections meet performance standards, even under demanding conditions.

Additional Considerations

Consider factors such as ease of installation, environmental exposure, and connection type. For instance, heat shrink tubing is excellent for maintaining neatness and flexibility, while silicone sealants are better suited for irregularly shaped surfaces.

Don’t overlook the importance of compatibility. Guarantee that the materials in the sealing solution match the temperature and resistance requirements of the connection. Using suboptimal materials could weaken the seal and compromise its protective qualities.

Finally, always adhere to manufacturer guidelines and best practices for installation. This ensures that the sealant delivers reliable protection over time.

Select the Best Sealing Solution

Proper sealing is essential to maintaining the functionality and safety of vehicle wiring systems. Whether you opt for heat shrink tubing, silicone sealants, or grommets, the right choice depends on the needs of the project.

For a streamlined and effective solution, consider adhesive-lined heat shrink tubing, especially for high-risk areas. This versatile option excels in providing a durable, water-resistant seal that stands up to wear and environmental challenges.

Remember, when deciding what type of sealing to use for vehicle wiring connections, quality materials and precision installation will supply long-term results.

You must login to post comments.