Dos and Don’ts of Fixing Automotive Electrical Problems

Dos and Don’ts of Fixing Automotive Electrical Problems

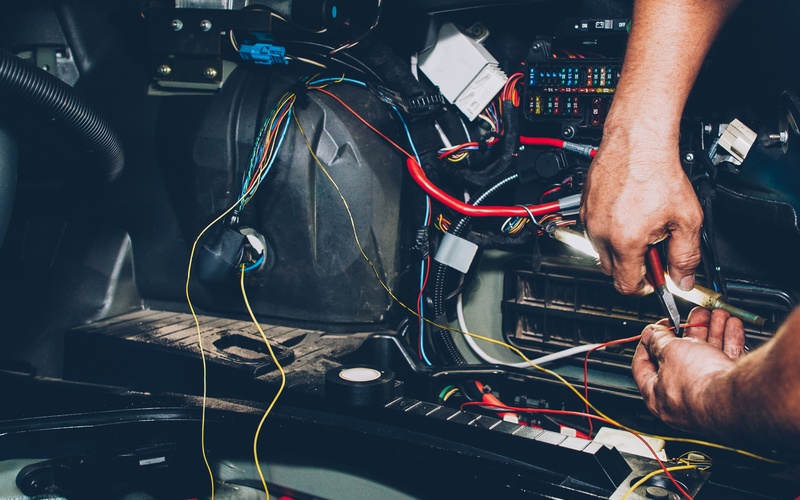

Automotive electrical systems determine a vehicle’s performance and safety. From the starter motor to the advanced infotainment systems, automotive electronics have become more sophisticated in modern vehicles.

However, dealing with electrical issues in your car requires ample knowledge. Whether you’re a professional or DIY mechanic, understanding the dos and don’ts of fixing automotive electrical problems can save you from frustrations, wasting time, and making costly errors.

Why Fixing Electrical Problems Requires Special Attention

Automotive electrical systems are intricate and sensitive to improper handling. Unlike mechanical parts, electrical components rely on wiring, connectors, and software controls to function correctly. For example, something as small as a misaligned wire or poorly installed 6-pin connectors can disrupt crucial functions like ignition, lights, or even vehicle diagnostics. This means every repair requires meticulous attention to detail.

Electrical faults also pose serious safety risks. Poorly executed fixes can lead to short circuits, fire hazards, or damage to sensitive onboard electronics. By following this list of best practices and mistakes to avoid, you can conduct electrical repairs on your vehicle safely.

Do Diagnose the Problem Accurately

Conducting an accurate diagnosis is the first step in resolving automotive electrical problems. Start with the vehicle’s symptoms—like flickering lights, a dead battery, or malfunctioning sensors—and work your way to the root cause using diagnostic tools.

Modern vehicles come with onboard diagnostic (OBD) systems, which can make troubleshooting more straightforward. An OBD scanner can provide error codes, pinpointing which system or component is malfunctioning. Once you have the error code, refer to the vehicle’s service manual for precise guidance on how to proceed.

Incorrect diagnosis is a common pitfall. Substituting parts or connectors randomly to fix the issue can worsen the situation.

The key is to avoid guesswork. Always support the diagnosis with objective evidence from tools and tests.

Do Invest in High-Quality Tools and Equipment

A basic toolkit should include a multimeter, wiring diagrams, fuse pullers, and insulated tools. Advanced repairs may require a soldering kit, electrical probes, or specialized software for module reprogramming.

Using incorrect or low-quality tools can compromise the integrity of repairs. For instance, using uninsulated tools while working on live systems increases the risk of short circuits. Similarly, improper crimping tools can damage connectors, leading to intermittent faults.

Always use high-quality tools that are appropriate for automotive repairs. The design of many automotive tools meets electrical standards, so investing in them will support safe and successful repairs.

Don’t Skip Safety Measures

One of the cardinal rules when working on any vehicle’s electrical system is to ensure safety for both you and the car. Start by disconnecting the battery to eliminate the risk of electric shocks. Wear insulated gloves, and always check for live currents with a multimeter before touching wires.

Ignoring safety precautions is dangerous. This misstep can result in severe consequences, including electrical burns and component damage. Act carefully and always wear safety gear when working with wiring.

Don’t Perform Repairs Without Training

Without proper training or knowledge, you’re putting yourself and the vehicle in harm’s way. Delving into complex circuits without thorough understanding is likely to result in expensive mistakes or injuries. Consulting a certified mechanic is the best move if you are unsure about handling a particular repair.

Do Handle Electrical Wires Carefully

Wiring is the backbone of automotive electrical systems. Properly managing wire connections, length, and insulation can prevent issues like voltage drops, overheating, or system malfunctions. When repairing wires, ensure they are correctly stripped, soldered, and insulated. Use wire sleeves or conduits for further protection, particularly in areas exposed to heat or friction.

Avoid makeshift solutions when dealing with wires. Taping loose wires or using connectors that aren’t designed for automotive use can cause temporary fixes that fail quickly. For instance, poorly attached connectors can cause flickering power in electrical circuits, affecting systems such as the alternator and starter motor.

Being meticulous with wiring practices will ensure the durability and reliability of your repairs. Always follow the vehicle’s wiring diagram to guarantee accurate repairs.

Don’t Overlook the Importance of Grounding

Proper grounding plays an essential role in automotive electrical systems. A bad ground connection can cause erratic behavior in lights, sensors, and even the engine control unit (ECU). Thus, verifying ground wires’ integrity and attachment points is an essential step of every electrical repair.

A common mistake is skipping the inspection of ground points. Dirt, rust, or loose connections can disrupt the grounding, leading to voltage instability. Use a wire brush to clean ground connections and ensure they are tight and corrosion-free. Applying dielectric grease can also protect ground points from damage.

Do Test the Vehicle’s Operation

Testing is the final step in fixing automotive electrical issues. After completing repairs, test the affected system to verify its functionality. Use diagnostic tools to check error codes and measure voltage, resistance, or current across relevant circuits.

Rushing this step can leave undetected faults that may emerge later as bigger problems. Thorough testing is necessary when intricate repairs involving multiple systems. Ensuring that the repaired component aligns with the vehicle manufacturer’s specifications completes the job properly and avoids recurring problems.

Don’t Use Incompatible Parts

Using incompatible electrical components can cause functional mismatches or permanent damage. Always verify the specifications of replacement parts, connectors, and modules before installation.

Do Document All Automotive Repairs

Another error some mechanics make is neglecting to document repairs. Keeping detailed records of parts replaced, connectors used, and error codes resolved ensures traceability for future maintenance or troubleshooting.

Don’t Ignore Software Updates

Many modern vehicles require periodic software updates to their onboard systems. Neglecting these updates can result in software glitches or compatibility issues with new components. Stay on top of software updates to keep the vehicle operating correctly.

Conclusion

Mastering the dos and don’ts of fixing automotive electrical problems supports safe, efficient, and lasting vehicle repairs. You can confidently tackle electrical issues by carefully diagnosing problems, using high-quality tools, and adhering to the safety best practices when handling live wires.

Whether you’re fixing wiring malfunctions, grounding circuits, or replacing connectors, taking a thoughtful and meticulous approach ultimately saves time and resources. Remember, the growing complexity of modern vehicles demands both knowledge and precision.

You must login to post comments.