Why You Should Use an 8-Cavity Connector

Why You Should Use an 8-Cavity Connector

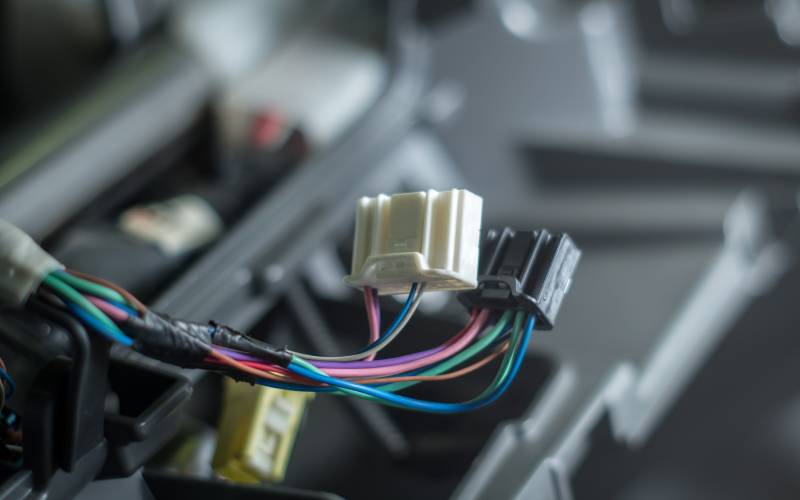

Automotive engineering demands precision, reliability, and efficiency in every component. Connectors play a vital role in establishing and maintaining electrical connections between various systems in the vehicle.

These connectors come in various sizes, styles, and shapes; we’ll explain why you should use an 8-cavity connector. These little components offer a solid balance of size, efficiency, and power within a wide range of systems to optimize performance.

The Role of Connectors in Automotive Engineering

First, you should understand the role connectors play in automotive systems. Connectors link the electronic components and signals with power transmission.

These systems can work for driver assistance modules and infotainment systems in the center console and make the light on the rear passenger side light up. This happens in tandem with all the stresses of a moving vehicle. Even a minor flaw in a connector can compromise the functionality of various systems, underscoring the importance of selecting the right one for the job.

The Design of an 8-Cavity Connector

An 8-cavity connector, as its name suggests, accommodates eight individual terminals in its design. This configuration allows it to connect multiple circuits at once while maintaining reliability and organization. Manufacturers build these connectors with high-quality materials, such as thermoplastics and strengthened composites. These connectors can withstand automotive applications without losing their connections.

Versatility Across Automotive Applications

One of the primary reasons to choose an 8-pin connector is its remarkable versatility. It has applications across many automotive functions, from powertrain systems to lighting and infotainment modules.

Its balanced terminal capacity allows for driving various subsystems in a vehicle without bloating the wiring architecture. Adaptability ensures it meets the needs of small-scale and large-scale applications, which is particularly beneficial in vehicles with limited space for wiring.

Simplifying Wiring Complexity

Automotive wiring systems are labyrinthine by nature, making maintenance and upgrades complicated. The 8-cavity connector simplifies things by consolidating multiple circuits into a single modular unit. This eliminates individual connections, reducing the risk of errors during installation. A neat, organized setup also facilitates diagnostics and troubleshooting, reduces vehicle weight, and can shorten assembly times on production lines.

Durability in Harsh Conditions

Another reason why you should use an 8-cavity connector is that it maintains reliable connections in harsh conditions. Vehicles often experience high temperatures, vibrations, moisture, and exposure to debris during operation and when parked.

The 8-pin connector can overcome environmental challenges. It features seals, gaskets, or hydrophobic components to resist water ingress and support connectivity, even in wet conditions. The rugged design absorbs vibrations and resists wear, reducing the likelihood of loose connections or degradation over time.

These connectors can hold up under extreme heat generated by internal automotive systems or external weather conditions. Durable connectors are non-negotiable for engineers designing vehicles that must endure high heat.

Enhanced Scalability for Evolving Systems

Modern automotive engineering is moving toward modular and scalable designs to accommodate fast-evolving industry trends, such as semi-autonomous functionality, increased vehicle electrification, and more advanced infotainment systems. Thanks to its structure, the 8-cavity connector enables seamless integration of existing and future systems.

Whether you’re building an entirely new vehicle platform or upgrading existing models, this connector’s standardized design facilitates scalability. Engineers can easily expand subsystems, add or modify circuits, and integrate backward compatibility without making significant modifications.

Optimization for Signal Integrity

Signal integrity is vital for vehicles that rely on sensors, such as advanced driver-assistance systems (ADAS) or GPS-based functionalities. The 8-cavity connector limits signal loss by maintaining consistently strong electrical contacts between its terminals. The insulating materials also play a role in minimizing electromagnetic interference because they preserve signal quality in high-density setups.

Signal interruptions or delays might compromise critical functions, such as braking or collision-avoidance systems, further highlighting the connectors’ role in driver safety and system reliability. Utilizing 8-cavity connectors is a smart decision for automotive engineers prioritizing the consistency and reliability of onboard signals.

Meeting Automotive Industry Standards

The automotive industry follows strict guidelines for component manufacturing for the sake of performance and safety. The 8-pin connector meets global automotive standards, from ISO certification to RoHS compliance. Manufacturers often tailor these connectors to pass rigorous testing protocols, which include cyclical temperature testing, mechanical stress tests, and electrical load assessments.

Compatibility With Advanced Manufacturing Practices

The push toward automation in manufacturing processes makes precision and uniformity essential at every stage of production. One of the reasons for the 8-cavity connector’s popularity is that it works with modern automotive manufacturing lines while offering a sleek design that will work in the future. It aligns perfectly with modern automotive manufacturing lines. The modular design, standardized size, and clearly labeled terminal positions support placement during automated soldering or crimping.

Compatibility reduces human errors while improving quality assurance metrics—an essential consideration for brands aiming for efficiency in high-volume production. Automated assembly processes also expedite the deployment phase, creating smoother workflows for manufacturers.

Cost Efficiency in the Long Run

Although premium materials and advanced engineering might make quality connectors marginally more expensive upfront, the 8-cavity connector ultimately saves costs in the long term. Its durability reduces the likelihood of maintenance or replacement over the vehicle’s lifecycle.

The cost-benefit relationship becomes particularly evident in fleet operations or mass market production, where streamlined maintenance schedules and extended component lifespans directly contribute to savings.

The 8-Cavity Connector: A Practical Choice for Precision

To excel in modern automotive engineering, every component must blend functionality, reliability, and scalability. The 8-cavity connector checks all these boxes and more!

Its versatility across systems, ability to endure environmental challenges, and support for scaling make it a practical choice that meets the demands of even the most ambitious projects. Engineers investing in dependable wiring solutions should look no further than 8-pin connectors when designing systems that prioritize safety, performance, and durability.

At Connector Experts, we understand the importance of reliable automotive connectors for seamless integration and optimal performance. If you’re seeking top-quality 8-pin pigtail connectors for your automotive projects, look no further. Visit our website or contact our team today to explore our wide range of connectors and find the perfect solution for your wiring needs.

You must login to post comments.