How To Select a Reliable Supplier for 5-Cavity Connectors

How To Select a Reliable Supplier for 5-Cavity Connectors

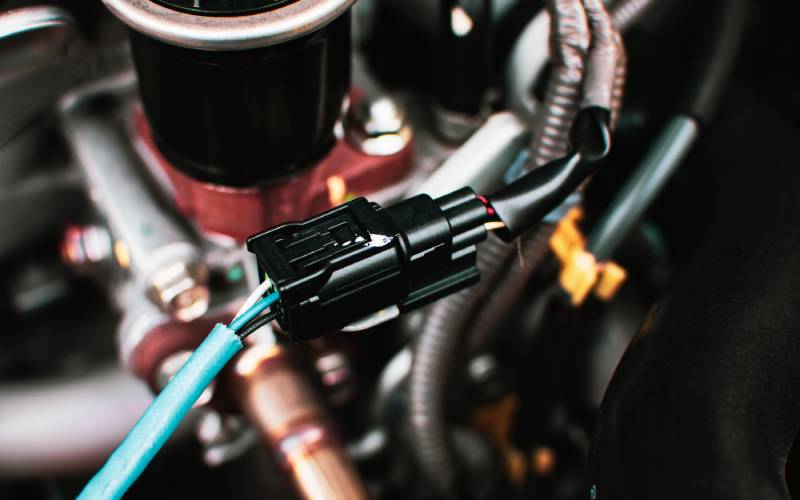

Choosing a supplier for your automotive electrical connectors is an important step when you’re putting vehicles together. These connectors create and maintain seamless communication between different electronic systems in vehicles.

For automotive manufacturers, knowing how to select a reliable supplier for 5-cavity connectors can make a huge difference in maintaining efficient production and avoiding costly delays. Connector Experts can provide you with comprehensive insights into selecting a trustworthy supplier for your connectors, focusing on quality standards, supply chain reliability, and long-term partnership potential.

Understanding the Importance of 5-Cavity Connectors

Five-cavity connectors are useful and beneficial in nearly every modern vehicle. They guide the flow of information and power between various components, such as control units and sensors.

Given their critical role, connector failure can lead to malfunctions. Automotive manufacturers need to prioritize reliability and performance when choosing these components. By selecting the right connector supplier, your vehicles maintain optimal functionality while enhancing customer satisfaction and brand reputation.

Evaluating Supplier Experience and Expertise

When considering potential suppliers, it’s always a good idea to check their experience and expertise with connectors, 5-cavity or otherwise. Suppliers with a proven track record in the automotive industry are more likely to understand the requirements and standards for these components.

Look for long-standing suppliers with experience in the game; they likely understand the industry and know how to utilize this technology. An experienced supplier will not only provide high-quality products but will also offer valuable insights and support throughout the procurement process.

Assessing Quality Standards and Certifications

Part of choosing a supplier is finding one who offers quality products. To receive top-notch components, verify that the supplier adheres to industry standards and possesses relevant certifications. ISO 9001 and IATF 16949 are two certifications that indicate a supplier’s commitment to quality management systems and automotive-specific standards, respectively.

You may also want to ask about the supplier’s quality control processes, such as inspection procedures and testing methodologies. Reliable suppliers have strongly defined quality assurance measures in place so that they offer consistent and reliable products for their customers. By prioritizing quality standards, you can minimize the risk of defects and guarantee your vehicles meet high performance and safety standards.

Analyzing Production Capacity and Lead Times

Timely delivery is an important factor when partnering with a connector supplier. The sooner you get your products, the more likely you are to stay on schedule, meet customer demand, and avoid delays.

Evaluate a supplier’s production capacity and lead times before making a decision. Assess whether the supplier has the necessary infrastructure and resources to meet your volume requirements, both short and long-term.

You may want to ask about their lead times and ability to accommodate changes in demand. A supplier with flexible production capabilities and reliable lead times will help you avoid costly delays and ensure a smooth manufacturing process. By choosing a supplier with high production capabilities, manufacturers can maintain a consistent supply chain and respond to market fluctuations.

Examining Supply Chain Reliability and Risk Management

When figuring out how to select a reliable supplier for 5-cavity connectors, you should look into the reliability of the supply chain. Dependable suppliers offer well-established processes and strategies that can control disruptions and minimize risks. Assess their approach to risk management, including their ability to source raw materials from multiple suppliers and maintain buffer stock levels.

Whenever possible, check out your potential partner’s logistics and distribution capabilities. Can they deliver products on time, even in the face of unforeseen challenges? Manufacturers can protect their production schedules and maintain a competitive edge by partnering with suppliers that prioritize a reliable supply chain.

Exploring Technological Capabilities and Innovation

Pay attention to technological advancements, and make sure that your supplier is keeping up with the latest trends. A forward-thinking supplier will invest in cutting-edge manufacturing processes, such as automation and precision engineering, to produce high-quality components.

Check in with them and ask if they’re currently improving or adapting to modern industry trends. By working with a supplier that emphasizes innovation, you can benefit from the latest advancements in connector technology and enhance the performance and reliability of your vehicles.

Investigating Cost-Effectiveness and Pricing Models

While you should always focus on quality and reliability, sometimes your decision of connectors comes down to cost. Analyze the supplier’s pricing models, and compare them to competitors to receive the best value for your investment. Keep in mind that the lowest price doesn’t equal the best quality, but you may find suppliers of similar reliability with noticeable price differences!

It never hurts to ask your potential supplier about possible discounts or incentives for bulk orders or long-term partnership deals. A supplier with transparent and competitive pricing will help you optimize your procurement budget and maximize your return on investment.

Building Strong Communication and Support Systems

Effective communication and support are essential components of a successful supplier relationship. When evaluating potential suppliers, assess their communication channels and responsiveness. Reliable suppliers are easy to contact, and you can bring up questions or concerns while receiving regular updates and order statuses.

You should also try to keep post-sales support in mind when deciding if you want to stick with a supplier. Work with one that emphasizes clear communication and offers optimal support to help you address issues while maintaining a strong and professional business partnership.

Establishing Long-Term Partnerships and Collaboration

Finally, consider the potential for establishing a long-term partnership with your chosen supplier. It’s beneficial to both you and your supplier to build a collaborative relationship based on trust and mutual benefits.

Look for suppliers that demonstrate a willingness to work closely with your team, offering customized solutions and adapting to your evolving needs. By fostering a strong partnership, you can ensure consistent quality, reliability, and innovation in your 5-cavity connectors. This ultimately drives your success in the automotive market!

As you strive to enhance the quality and reliability of your automotive components, Connector Experts is here to support your journey with our high-quality 5-pin plug connectors. We invite you to explore our extensive range of products that meet the rigorous demands of the automotive industry. Trust in our expertise and commitment to excellence to help you achieve seamless connectivity and superior performance in your vehicles. Contact us today to discuss your needs and find the perfect connectors for your applications.

You must login to post comments.