Benefits of Using 6-Cavity Connectors in Automotive Design

Benefits of Using 6-Cavity Connectors in Automotive Design

One of the guiding principles behind automotive design is that we’re always striving for new ideas. We can make the slightest changes or add new components to unlock bold and exciting new features that would otherwise seem impossible.

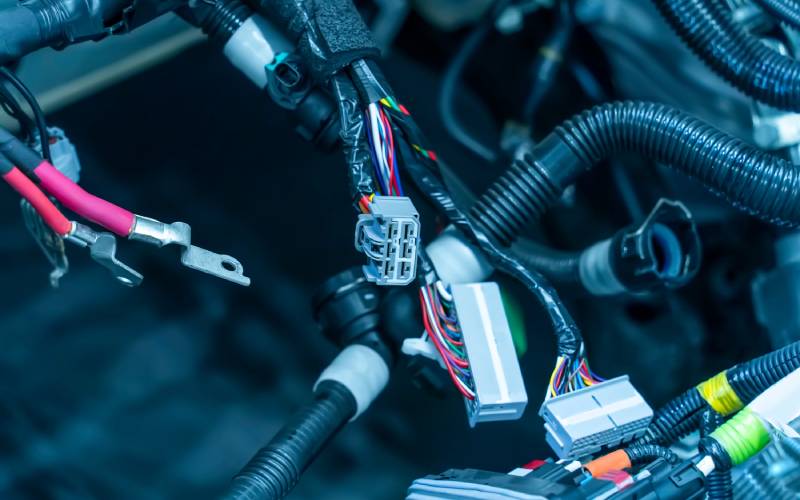

Electrical connectors allow us to establish connections and transmit functions between different systems. Today, Connector Experts is here to explore some of the benefits of using 6-cavity connectors in automotive design. These connectors can create new systems, enable new operations, and streamline the manufacturing process to be faster and more reliable.

Enhancing Electrical Efficiency

The first advantage of these connectors is the opportunity to enhance electrical efficiency. Six-cavity connectors streamline electrical systems by providing a compact solution for multiple wire connections. Fewer connectors throughout the vehicle allow us to significantly reduce the complexity of the wiring harness. This simplification leads to improved flow and distribution of electrical power throughout the vehicle.

A key attribute of 6-cavity connectors is their ability to accommodate a variety of wire gauges. This flexibility allows engineers to optimize the electrical architecture for different components without needing multiple connector types. The result is a more efficient electrical system that minimizes power loss and enhances overall vehicle performance. Reducing the wiring complexity decreases the likelihood of electrical faults, thus improving the reliability and safety of the vehicle.

Improving Design Flexibility

Design flexibility is another significant advantage offered by the right electrical connectors. Automotive engineers must balance functionality with aesthetic and spatial constraints. The compact size and versatile configuration of 6-cavity connectors provide engineers with the flexibility needed to meet these demands.

One aspect of design flexibility is the ability to create systems that can accommodate multiple components in tighter spaces. The compact nature of 6-cavity connectors allows us to use them in tight areas where larger connectors might not fit. This capability is particularly important in modern vehicles that utilize newer features and technological advancements. Engineers can leverage these space-saving connectors to optimize the layout of electrical systems without compromising on vehicle design or functionality.

Streamlining Manufacturing Processes

Six-cavity connectors do more than benefit the final product; they significantly streamline the manufacturing process. Adopting these connectors simplifies assembly, reducing time and labor costs associated with vehicle production.

One of the main ways 6-cavity connectors streamline manufacturing is by reducing the number of separate connectors and wires needed in a vehicle. By consolidating multiple connections into a single unit, these connectors minimize the assembly steps required to complete the wiring harness. Simplifying the process leads to faster assembly times and reduces the potential for errors during production.

Enhancing Vehicle Safety

Safety is always a big concern when designing automotive electrical systems, and you can use 6-cavity connectors to enhance safety features. The right connectors provide secure and reliable electrical connections that reduce the risk of electrical failures and malfunctions.

One of the key safety features of 6-cavity connectors is their robust locking mechanisms. This mechanism fastens the connectors and keeps them secure, even under harsh driving conditions. By preventing accidental disconnections, 6-cavity connectors maintain the integrity of the vehicle’s electrical system, reducing the likelihood of failures that could compromise safety.

Supporting Advanced Technology Integration

Modern vehicles utilize advanced technology, from infotainment systems to driver-assistance features. One of the benefits of using 6-cavity connectors in automotive design is that we can integrate these features seamlessly and provide efficient and reliable connections.

One area where 6-cavity connectors excel is in the connection of complex electronic modules. These connectors can accommodate multiple signal and power lines within a single unit, simplifying the wiring architecture for advanced systems. Whether connecting sensors, cameras, or control units, 6-cavity connectors deliver the necessary data and power efficiently.

Optimizing Weight and Space

Engineers and manufacturers are always looking for ways to enhance fuel efficiency and performance while reducing weight and optimizing space. When we take all these factors into consideration, it makes sense to use 6-cavity connectors. They are lightweight, conveniently-sized connectors that can maintain stable electrical connections.

The compact size of 6-cavity connectors allows us to seamlessly integrate them into a vehicle’s design and minimize the space occupied by wiring harnesses. This space optimization is especially valuable in electric and hybrid vehicles, where battery and powertrain components require additional room. By reducing the size of electrical systems, 6-cavity connectors enable engineers to maximize the use of available space for other critical components.

Facilitating Maintenance and Repair

Maintenance and repair are integral aspects of vehicle ownership, and 6-cavity connectors simplify these processes for technicians and vehicle owners. Their design makes it incredibly easy to access and inspect these areas, as well as replace electrical connectors. This simplicity helps us keep vehicles in good condition by making them more accessible and easier to repair.

Another key advantage of 6-cavity connectors is their modularity. The ability to disconnect and reconnect wires without specialized tools facilitates quick and efficient maintenance operations. Technicians can access the connectors easily, enabling them to diagnose and address electrical issues promptly.

The intuitive design of 6-cavity connectors also reduces the complexity of troubleshooting electrical problems. With fewer connection points to inspect, technicians can identify and fix faults with greater accuracy and speed. This efficiency translates to reduced downtime for the vehicle and increased customer satisfaction.

Supporting Sustainability Initiatives

Sustainability is a growing priority in the automotive industry, and 6-cavity connectors support efforts to reduce the environmental impact of vehicles. Their design contributes to eco-friendly practices in several ways, aligning with the goals of sustainable mobility.

One aspect of sustainability is the reduction of waste during production and end-of-life disposal. We can manufacture 6-cavity connectors with high-quality materials that aid in durability and longevity. By replacing them less frequently, we can minimize waste.

In addition, 6-cavity connectors contribute to the recyclability of electrical systems. We can process and reuse their materials to support a circular economy in the automotive industry. By facilitating recycling efforts, these connectors reduce the environmental footprint of vehicle production and disposal.

If you’re looking to elevate your automotive projects with efficient and reliable electrical solutions, explore our range of 6-pin electrical connectors. Connector Experts specializes in supplying components that streamline design, enhance safety, and support advanced technologies in vehicles. Take the next step in optimizing your automotive innovations by incorporating our top-of-the-line connectors. Contact us today to learn more about how our 6-pin electrical connectors can meet your needs and transform your vehicle designs.

You must login to post comments.