Future Trends and Prospects of 8-Cavity Connector Technology

Future Trends and Prospects of 8-Cavity Connector Technology

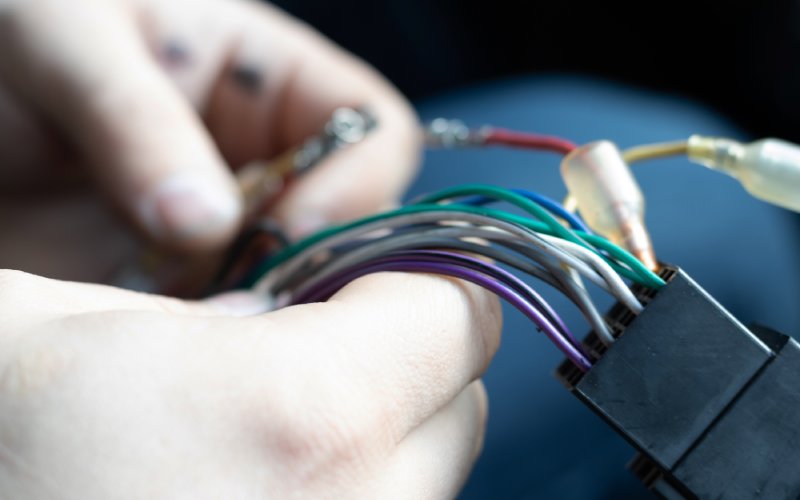

The automotive industry is constantly looking for new technology and innovations to make driving safer and more enjoyable. Everything, from headlights to touchscreen infotainment systems, relies on small components that provide drivers with convenience and functionality.

Electrical connectors are some of those small components that make a big difference, and engineers are constantly improving them. Connector Experts is here to discuss some of the future trends and prospects of 8-cavity connector technology and how we can implement it in electrically complex vehicles.

The Rising Importance of 8-Cavity Connectors

We’re witnessing a surge of complex electrical systems in modern vehicles, meaning we must develop more efficient and reliable connectors. 8-cavity connectors are powerful, offer a wide range of versatility, and are a go-to solution for engineers and manufacturers looking to solve problems with electrical systems. These connectors offer a higher density of connections within a compact space, making them ideal for the growing number of electronic components in today’s vehicles.

Advantages of 8-Cavity Connectors

One of the key advantages of 8-cavity connectors is their ability to handle multiple connections simultaneously. This feature reduces the number of connectors needed in a system, simplifying the wiring harness and reducing the overall weight of the vehicle. 8-cavity connectors are good at withstanding harsh automotive environments, ensuring long-term reliability and performance.

Another significant benefit is the ease of installation and maintenance with this type of connector. With fewer parts to manage, automotive engineers can streamline the assembly process and reduce the likelihood of errors. The modularity of 8-cavity connectors also allows for easy upgrades and modifications, making them a future-proof solution for evolving automotive technologies.

Emerging Trends in 8-Cavity Connector Technology

Engineers and manufacturers can shape the future of connector technology by looking at several emerging trends. One trend is the increasing miniaturization of electronic components, which demands smaller and more efficient connectors. Engineers are focusing on developing connectors that can deliver high performance while occupying minimal space, enabling more compact and streamlined vehicle designs.

Another trend is the integration of smart features into 8-cavity connectors. We can equip these connectors with advanced sensors and diagnostic capabilities, allowing real-time monitoring of electrical connections. This innovation enhances the overall reliability of the vehicle’s electrical system and allows for predictive maintenance, reducing downtime and repair costs.

Applications in Electric and Autonomous Vehicles

Electric and autonomous vehicles are driving the demand for advanced connector technology. The high power requirements of electric vehicles necessitate connectors that can handle significant currents while maintaining safety and efficiency. Engineers can optimize these connectors to meet industry demands, ensuring seamless power delivery and data communication within the vehicle.

In autonomous vehicles, there’s a much greater need for sophisticated sensors and control systems that require connectors to support high-speed data transmission and robust signal integrity. Manufacturers and engineers can design 8-cavity connectors to meet these stringent requirements, providing the reliability and performance needed for self-driving vehicle operation.

Enhancing Safety and Reliability

As vehicles become more technologically advanced, some of the future trends and prospects of 8-cavity connector technology involve the safety and reliability of vehicle electrical systems. Companies engineer and utilize 8-cavity connectors to enhance safety, reliability, and functionality.

We can employ high-quality materials and precision manufacturing techniques so these connectors offer robust protection against environmental factors such as vibration, temperature fluctuations, and moisture. These attributes help prevent electrical failures, which could otherwise lead to critical safety issues.

Environmental Considerations and Sustainability

With growing awareness of climate change and environmental impacts, the automotive industry is increasingly prioritizing sustainability. 8-cavity connector technology is advancing in alignment with these goals by focusing on eco-friendly design and materials.

Manufacturers are exploring the use of recycled and biodegradable materials in the production of these connectors, reducing the environmental footprint of automotive components. Additionally, the durability and efficiency of 8-cavity connectors contribute to longer vehicle lifespans and decreased resource consumption, as reliable connectors minimize the need for frequent replacements and repairs.

Energy-efficient manufacturing processes also play a significant role in the development of sustainable 8-cavity connectors. We can aim for innovations in production techniques to reduce energy consumption and minimize waste.

Future Prospects and Innovations

The future of 8-cavity connector technology looks promising, as engineers are working to enhance functionality, efficiency, and adaptability in the automotive sector. One of the most anticipated developments is the incorporation of artificial intelligence and machine learning capabilities into these connectors. By leveraging AI, 8-cavity connectors could autonomously optimize performance based on real-time data, allowing for adaptive adjustments that increase the efficiency of a vehicle’s electrical systems.

Another area of innovation is in wireless connectivity solutions. As the automotive industry gradually shifts away from extensive wiring systems, the development of wireless 8-cavity connectors presents an exciting frontier. These connectors could eliminate the need for traditional wiring, leading to significant reductions in vehicle weight and complexity.

Collaboration and Standardization Efforts

Collaboration and standardization are essential for the widespread adoption of electrical connector technology. Industry stakeholders, including automotive manufacturers, connector suppliers, and standards organizations, are working together to establish common guidelines and specifications. This collaborative approach ensures mutual benefits and compatibility across different vehicle platforms and enhances the overall efficiency of the automotive supply chain.

Overcoming Challenges and Addressing Concerns

While the future of connector technology looks promising, there are still several challenges and concerns to address. For starters, we need to improve general thermal management. The increasing power densities in modern vehicles generate significant heat, which can affect the performance and longevity of connectors. Engineers are developing innovative cooling solutions and thermal management techniques to mitigate these issues.

Another concern is the potential for increased electromagnetic interference (EMI) in densely packed electrical systems. Engineers working on connectors need to find shielding and grounding techniques to minimize EMI and ensure reliable signal transmission.

As the automotive industry continues to evolve, it is crucial for professionals to stay ahead of the latest in connector technology. At Connector Experts, we dedicate ourselves to providing high-quality electrical connectors from a wide range of innovative 8-pin connectors.

Whether you are developing electric vehicles or enhancing traditional automotive systems, our connectors can streamline your projects and improve efficiency. Browse our extensive online catalog to find the part that works for you, or contact us anytime, and a team member will help you find what you’re looking for.

You must login to post comments.