Environmental Considerations for 3-Cavity Connectors

Automotive engineers strive to innovate while maintaining sustainability. Electrical connectors are vital components in modern vehicles, with many systems utilizing 3-cavity connectors. Connector Experts understands the environmental considerations for 3-cavity connectors. We’re here to explain the role of 3-cavity connectors and offer insights and practical strategies to maintain a greener and more sustainable future.

Understanding 3-Cavity Connectors

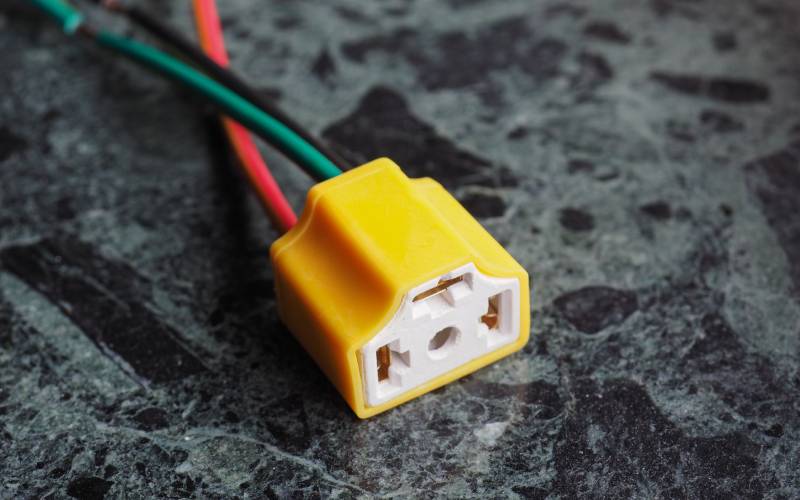

To appreciate the environmental considerations of 3-cavity connectors, you must first understand what they are. These connectors serve as an interface for electrical systems within vehicles, enabling the transmission of power and signals. Their compact design and efficiency make them a popular choice in modern automotive engineering.

Manufacturers and engineers must consider the materials they use in creating these connectors. Most commonly, we use plastics or metals with distinct environmental impacts. The material affects not only the performance but also the environmental footprint of the connectors.

Manufacturing processes also play a critical role. Techniques such as injection molding for plastic components and precision machining for metal parts can consume significant energy and resources. Understanding these processes helps engineers make informed decisions about the sustainability and longevity of their designs.

Material Selection and Sustainability

Selecting sustainable materials for 3-cavity connectors is an important part in maintaining their longevity. Engineers often face a trade-off between performance and environmental impact. When choosing materials, they may need to consider which ones are easier to recycle or which ones will have less of an environmental impact.

Plastics are commonplace for their durability and low cost but come with the environmental challenges of not being biodegradable and being harder to recycle. However, advancements in biodegradable plastics offer promising alternatives. These materials break down more easily in the environment, reducing their long-term impact.

Other common options are metals, which are much easier to recycle, making them a good sustainable option. Aluminum and copper are also popular in connector manufacturing for their conductivity and recyclability.

Energy Consumption in Manufacturing

The energy consumption associated with manufacturing 3-cavity connectors is another significant environmental consideration. High energy use not only increases production costs but also contributes to carbon emissions. Engineers should aim to minimize energy usage through efficient manufacturing processes.

Implementing energy-efficient machinery and optimizing production techniques can significantly reduce energy consumption. Using advanced injection molding machines that operate at lower temperatures can save energy while maintaining product quality.

Exploring renewable energy sources for manufacturing facilities can further decrease the environmental impact. Solar panels, wind turbines, and other renewable energy systems offer viable options for powering production lines sustainably.

Waste Management and Recycling

Another environmental consideration of 3-cavity connectors is proper waste management and recycling. The production process generates various types of waste, including plastic scraps, metal shavings, and chemical byproducts. Implementing robust waste management strategies ensures that these materials are disposed of or recycled properly.

Recycling programs for plastic and metal waste can significantly reduce the environmental footprint. Engineers should work with suppliers and manufacturers to establish recycling protocols for scrap materials. Encouraging recycling within the production facility itself also promotes sustainability.

Designing connectors with end-of-life recycling in mind enhances their sustainability. Easy-to-disassemble components facilitate recycling efforts, ensuring that valuable materials are recovered and reused, reducing the need for virgin resources.

Environmental Impact of Packaging

Packaging plays a big part when you’re looking at the environmental factors of 3-cavity connectors. The materials that you use in packaging and the methods of disposal can significantly impact the environment. Reducing packaging waste and using sustainable packaging materials are essential steps.

Engineers should prioritize using biodegradable or recyclable packaging materials. Options like cardboard, paper, and biodegradable plastics can replace traditional plastic packaging, reducing environmental harm.

Additionally, minimizing packaging size and weight reduces transportation emissions. Innovative packaging designs that protect products while using fewer materials contribute to sustainability efforts. Collaboration with suppliers to ensure eco-friendly packaging practices further enhances the environmental credentials of 3-cavity connectors.

Lifecycle Assessment and Environmental Impact

Conducting a lifecycle assessment (LCA) provides a comprehensive understanding of the environmental impact of 3-cavity connectors. LCA evaluates the environmental aspects associated with all stages of a product’s life, from raw material extraction to disposal.

Engineers can use LCA to identify areas where they can make environmental improvements. By analyzing each stage of the connector’s lifecycle, from manufacturing to end-of-life disposal, engineers gain insights into the most impactful areas.

LCA helps in making informed decisions about material selection, manufacturing processes, and waste management. It also provides a framework for continuous improvement, ensuring that environmental considerations are integrated into every aspect of the connector’s lifecycle.

Regulatory Compliance and Standards

Adhering to environmental regulations and standards is essential for automotive engineers. Various international and regional regulations govern the environmental impact of automotive components, including 3-cavity connectors. Complying with these regulations and statutes helps ensure legal stability and demonstrates a commitment to sustainable manufacturing.

Engineers should learn about regulations related to material use, energy consumption, emissions, and waste management. Incorporating these standards into the design and manufacturing processes ensures that 3-cavity connectors meet environmental requirements.

They may also aim to obtain certifications from recognized environmental bodies to enhance the credibility of the product. Certifications like ISO 14001 for environmental management systems signify a commitment to sustainable practices and can be valuable marketing tools.

Innovations in Eco-Friendly Connectors

The pursuit of sustainability has led to numerous innovations in the field of automotive electrical connectors. Researchers and engineers are continuously developing eco-friendly alternatives that reduce environmental impact without compromising performance.

One such innovation is the use of bio-based materials. These materials utilize renewable sources like plants and offer a sustainable alternative to traditional plastics. Bio-based connectors are biodegradable and have a lower carbon footprint, making them an attractive option for environmentally conscious engineers.

Another innovation is the development of connectors with reduced energy consumption. Advanced manufacturing techniques and energy-efficient designs contribute to lower energy use during production. These innovations not only benefit the environment but also reduce production costs, making them economically viable.

Collaboration for Sustainability

Achieving sustainability in automotive connectors requires collaboration across the supply chain. Engineers should work closely with suppliers, manufacturers, and customers to implement sustainable practices at every stage.

Collaboration with suppliers ensures that they source raw materials responsibly and that manufacturing processes adhere to environmental standards. Establishing transparent supply chains and fostering partnerships with environmentally conscious suppliers can improve sustainability efforts.

Connector Experts invites all professionals in the automotive industry to join us in finding eco-friendly solutions with automotive connectors. By focusing on sustainable designs, including the use of 3-wire electrical connectors, we can collectively reduce our environmental footprint and pave the way for a greener future. Let’s collaborate to make a significant impact.

You must login to post comments.