4 Applications for 2-Cavity Connectors in Various Industries

4 Applications for 2-Cavity Connectors in Various Industries

Every component, no matter how small, plays a vital role when it comes to engineering and manufacturing. Among these overlooked yet indispensable parts are 2-cavity connectors. While they may seem simplistic compared to other electrical connector options, 2-cavity connectors have plenty of unique and important applications in various industries. The Connector Experts are here to explain how these pieces work and how they benefit many fields of electrical engineering.

The Basics of 2-Cavity Connectors

Two-cavity connectors are compact, two-slot components that join two electrical circuits. Manufacturers design these connectors to handle both high and low power, making them incredibly versatile in a wide range of applications. Since they contain durable materials, they create a secure and reliable connection, which is critical in automotive manufacturing and other heavy-duty industries.

We most often see these connectors in confined environments where a reliable connection is essential. Their design allows for easy installation and maintenance, often without the need for specialized tools. This simplicity and reliability make 2-cavity connectors popular in many industries.

1. Automotive Industry Applications

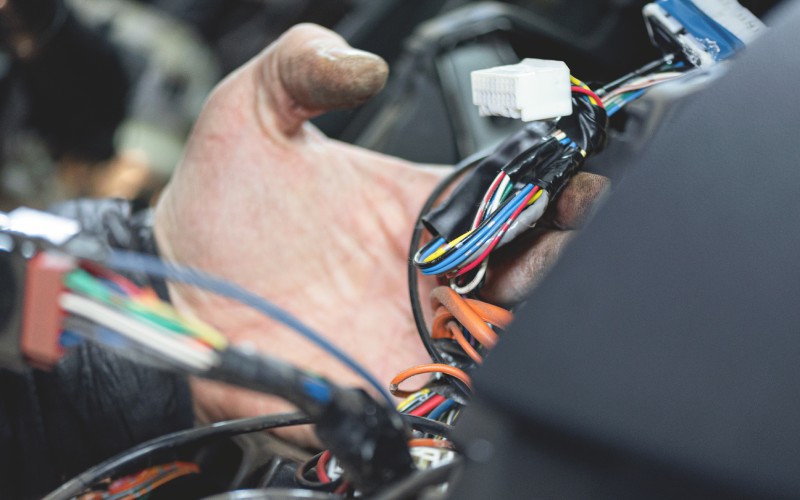

In the automotive industry, 2-cavity connectors serve multiple functions. One of the primary applications is in the electrical systems of vehicles. They connect sensors, lights, and other electronic components to the vehicle’s main control unit so that all parts of the vehicle can communicate. Connectors contribute to the performance and safety of vehicles.

Another critical application is in the engine compartment, where 2-cavity connectors frequently experience extreme temperatures and vibrations. Their design ensures that they can withstand these harsh conditions without compromising the integrity of the connection. Reliability is crucial for maintaining the vehicle’s performance and preventing potential failures.

Many engineers utilize these connectors in the vehicle’s infotainment system. They connect various components, such as the display screen, audio system, and navigation unit, creating seamless communication between these components and enhancing the driving experience.

2. Forklift Industry Uses

In forklifts, 2-cavity connectors are vital for connecting various electrical components. One of the primary applications is in the control system. These connectors link the control unit with the hydraulic system, supporting smooth and precise movements. Maintaining this connection is important for the safety and efficiency of the forklift and operator.

Another critical application is in the lighting system. Forklift operators may work in dim environments, making lighting crucial for safety. Two-cavity connectors form a reliable connection between the lights and the power source for consistent illumination.

Lastly, these connectors play a valuable role in the battery management system of electric forklifts, which are more popular than ever in industrial workspaces. They connect the battery to the control unit and other components for efficient power distribution. This is crucial for maximizing the forklift’s performance and battery life.

3. Marine Industry Applications

When looking at the applications of 2-cavity connectors in various industries, we can’t forget their role in boats and other marine equipment. One of their main applications is in the navigation system. These connectors link the various sensors and devices to the control unit, supporting accurate and reliable navigation.

Another important application is in the lighting system. Boats require lighting for safety, especially when boaters are out at night or in low-visibility conditions such as fog or storms. Two-cavity connectors ensure a secure and reliable connection between the lights and the power source, providing consistent illumination.

We also find these connectors in the communication system, which is important when operating the radio, GPS, or communicative devices. A dedication to maintaining a connection guarantees seamless communication among the crew and enhances safety and coordination on the water.

4. Construction Equipment Applications

In heavy construction equipment, 2-cavity connectors are essential for connecting various electrical components. One of the primary applications is in the control system. They link the control unit with the hydraulic and other systems, ensuring smooth and precise movements. This is vital for the safety of the operator and the longevity of the machinery.

Another important application is in the lighting system. Because many construction sites are active in dim conditions, the machine operators rely on connectors to produce light. The 2-cavity connectors create a reliable connection between the lights and the power source for consistent illumination.

The Advantages of Using 2-Cavity Connectors

One of the primary advantages of using 2-cavity connectors is their durability. Because manufacturers know they have to withstand harsh conditions, such as extreme temperatures and vibrations, they design them with those factors in mind. These precautions make them ideal for use in automotive, marine, and construction equipment applications.

Another significant advantage is their ease of installation. You usually don’t need specialized tools for setting up 2-cavity connectors. The emphasis on simplicity reduces the time and effort required for maintenance and repairs.

The compact design of these connectors is another notable advantage. Their small size allows us to use them in cramped spaces. While small, they don’t compromise the integrity of the connection, which makes them popular in various industries.

Challenges When Implementing 2-Cavity Connectors

Despite their many advantages, challenges may arise when implementing 2-cavity connectors. One of the biggest issues is forming a secure and reliable connection. This requires precise alignment and proper installation techniques, which may be difficult to achieve.

Another challenge is maintaining the integrity of the connection in harsh environments. While we design 2-cavity connectors to withstand extreme conditions, regular maintenance and inspections are necessary for their continued performance.

Additionally, the cost of these connectors can be a concern for some people. While the connectors offer numerous benefits, the initial investment may be higher than other models. However, the long-term advantages often outweigh the initial costs.

If you need reliable and high-performance solutions for your electrical connectivity needs, look no further than Connector Experts. With our extensive range of 2-wire connectors, you will create the connections you require for your application. Check out our online catalog to find the 2-cavity connector options that work best for your needs. If you have any questions, comments, or concerns, contact us anytime and a member of our team will be happy to assist you.

You must login to post comments.