Importance of 9-Cavity Connectors in EV Applications

Importance of 9-Cavity Connectors in EV Applications

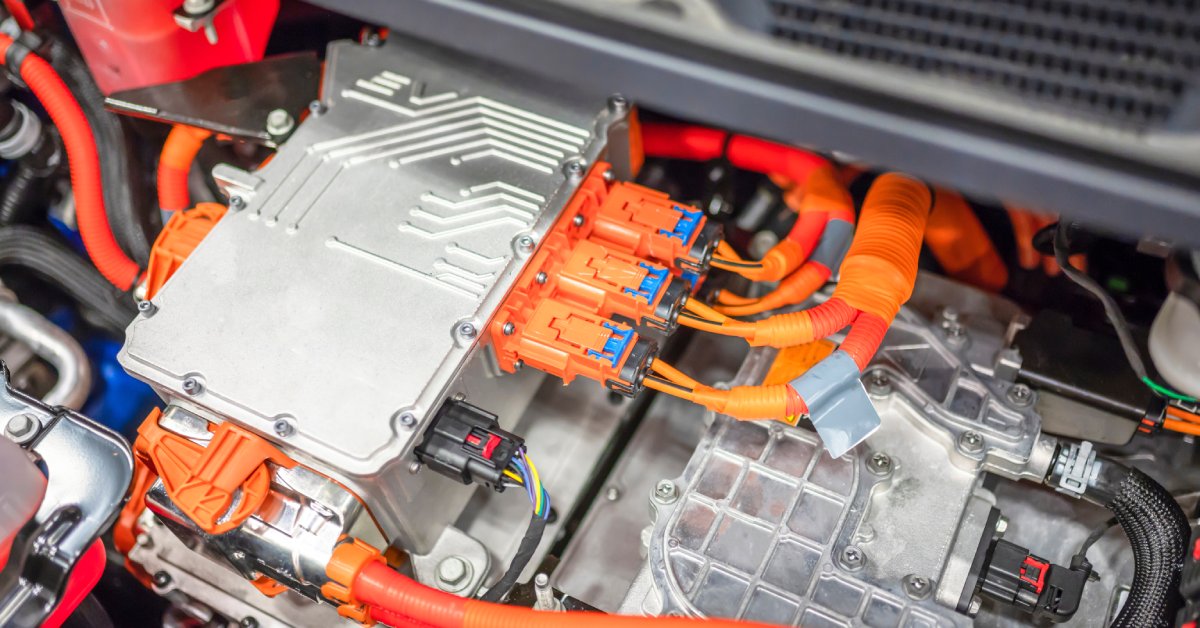

Electric vehicles (EVs) are rapidly transforming the automotive industry, promising a future of cleaner, more efficient transportation. While much attention goes to battery technology and electric drivetrains, the importance of connectors within these complex systems is equally noteworthy. Among these, 9-cavity connectors play a crucial role. Today, Connector Experts is here to explain the importance of 9-cavity connectors in EV applications and how they create reliable, long-lasting systems.

The Evolution of Electric Vehicle Connectors

Electric vehicles have come a long way since their inception, and so have the components that make them function. One critical element that has evolved is the connector. In traditional combustion engine vehicles, connectors were simpler, with fewer requirements for high voltage and current ratings. However, as EV technology advances, the need for specialized connectors is more important than ever.

Modern EVs require connectors that can handle higher voltages, provide robust connections, and ensure safety and reliability. This need was one of the main factors that led to the development of 9-cavity connectors, which offer a range of features tailored to the unique demands of electric vehicles.

Why 9-Cavity Connectors?

The choice of connectors in EV applications serves a specific purpose. Engineers select 9-cavity connectors for several compelling reasons. We cover the main reasons below.

Enhanced Reliability and Safety

One of the primary concerns in EV applications is safety. High-voltage systems pose significant risks, and any failure in connectors can lead to catastrophic consequences.

Manufacturers utilize 9-cavity connectors with safety in mind. These connectors can handle higher currents and voltages, making them ideal for the demanding requirements of electric drivetrains. They also feature advanced locking mechanisms that ensure a secure connection, minimizing the risk of accidental disconnection.

Furthermore, these connectors often incorporate sealing elements that protect against moisture and contaminants. This is particularly important in electric vehicles, as exposure to water or dust can compromise the integrity of the electrical system. By providing a sealed connection, 9-cavity connectors enhance the overall reliability and safety of EVs.

Simplified Wiring

Electric vehicles are known for their intricate wiring systems, and managing this complexity is a significant challenge for automotive engineers. Nine-cavity connectors offer a solution by condensing multiple connections into a single unit. This reduces the complexity of wiring and improves overall system efficiency.

The compact design of 9-cavity connectors allows for more efficient use of space within the vehicle. This is especially valuable in the tight confines of an EV’s chassis, where every inch of space is valuable. By streamlining the wiring layout, these connectors contribute to a cleaner and more organized electrical system.

Reduced Assembly Time and Costs

In the automotive industry, time and cost efficiency are critical factors. The use of 9-cavity connectors can significantly reduce assembly time, as they require less time to make individual connections. This translates to lower labor costs and shorter production cycles, ultimately benefiting manufacturers.

Additionally, the standardized design of these connectors ensures compatibility across different vehicle models and platforms. This standardization simplifies the sourcing and procurement process, reducing the overall cost of components. Automotive engineers can rely on 9-cavity connectors for consistent performance, regardless of the specific EV model they are working on.

Improved Performance and Efficiency

The performance of an electric vehicle hinges on the efficiency of its electrical system. Any loss of power due to poor connections can impact overall vehicle performance and range. 9-cavity connectors are designed to minimize resistance and ensure optimal power transfer. This efficiency is crucial for maximizing the range and performance of EVs.

Another part of the importance of 9-cavity connectors in EV applications is the reduced complexity of their wiring systems. This results in a more stable and reliable electrical system, enhancing the overall driving experience for EV owners.

Adaptability to Future Technological Advances

The automotive industry is constantly evolving, and electric vehicles are a top priority for many automotive manufacturers and brands. As new technologies emerge, such as advanced driver-assistance systems (ADAS) and autonomous driving capabilities, the need for robust and adaptable connectors becomes even more critical.

9-cavity connectors serve a distinct purpose and help future-proof many modern vehicles that we’re currently working on. Their versatile architecture allows for easy integration of additional circuits and functionalities, ensuring that EVs can accommodate technological advancements without significant modifications to the connector system. This adaptability is essential for keeping pace with the rapid evolution of electric vehicle technology.

Environmental Sustainability

Sustainability is a key driver behind the adoption of electric vehicles, and every component within an EV should align with this goal. Nine-cavity connectors contribute to environmental sustainability in several ways. For one, their compact design reduces the overall weight of the vehicle, leading to improved energy efficiency and reduced carbon emissions.

Secondly, manufacturers often produce these connectors using environmentally friendly materials and processes. These ideas align with the broader industry trend toward green manufacturing practices. By choosing components that prioritize sustainability, automotive engineers can contribute to the overall environmental benefits of electric vehicles.

Real-World Applications

To understand the practical impact of 9-cavity connectors, it’s a good idea to consider real-world applications. Many leading EV manufacturers are already integrating these connectors into their vehicle designs, recognizing their benefits for performance, safety, and efficiency.

Some of the most well-known and reliable electric vehicles, such as Nissan’s LEAF, Chevrolet’s Bolt, and Volkswagen’s ID, incorporate these connectors in their charging infrastructures. The result is improved reliability of the charging process.

The Future of 9-Cavity Connectors

Looking ahead, the role of 9-cavity connectors in EV applications is set to expand further. As electric vehicles become more mainstream and new models continue to enter the market, the demand for reliable and efficient connectors will only increase.

Advancements in connector technology, such as improved materials and enhanced design features, will continue to push the boundaries of what is possible. As a result, automotive engineers will have access to connectors that offer even higher performance, greater durability, and increased ease of use.

As the demand for innovative and efficient electric vehicle solutions grows, it’s crucial to partner with experts who understand the intricacies of connector technology. If you’re seeking reliable and high-performance components for your EV applications, including the highly versatile 9-pin connector or pigtail, look no further than Connector Experts. Reach out to us today to explore how we can support your projects and drive the future of electric mobility together.

You must login to post comments.