The Advantages of Using 6-Cavity Connectors in Complex Systems

When it comes to high-quality automotive engineering, the right components make a huge difference in the efficiency, reliability, and performance of complex systems. With so many wires and pieces connected, you want to make these systems as straightforward as possible without sacrificing quality. The Connector Experts are here to explore the advantages of using 6-cavity connectors in complex systems and why they may be right for you.

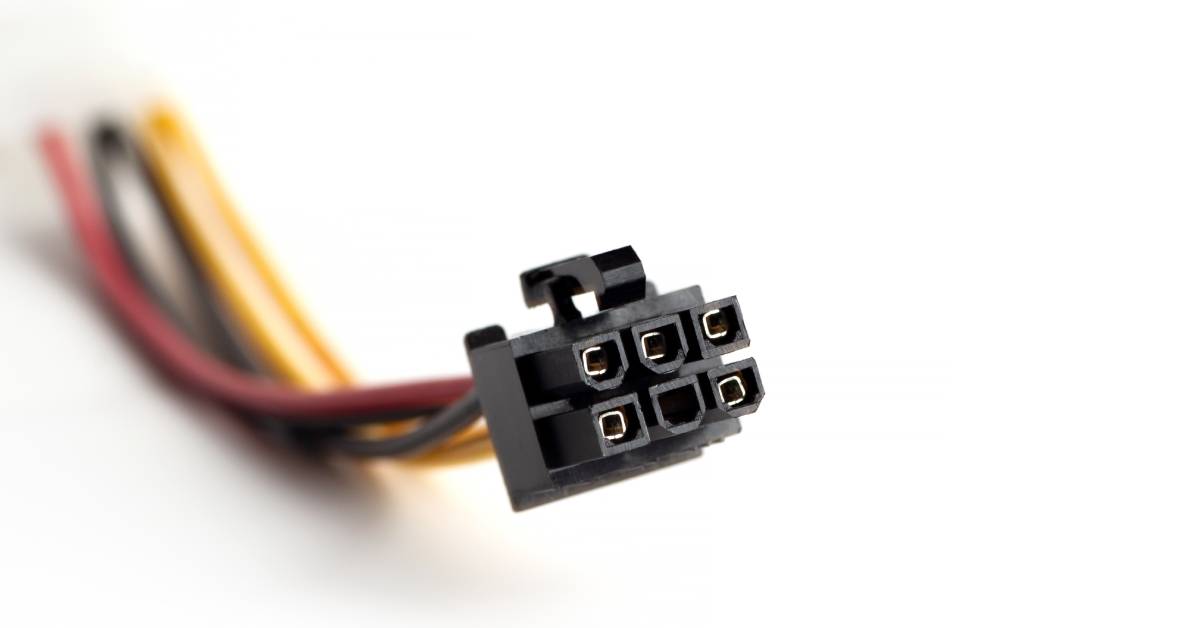

Understanding 6-Cavity Connectors

A 6-cavity connector facilitates the connection of multiple electrical circuits within a single, compact design. Manufacturers typically make them from durable materials such as thermoplastic and feature gold-plated contacts. The connectors resist corrosion and support reliable signal transmission.

Their six cavities accommodate various wire sizes and types, making them versatile enough to support a range of applications—from automotive wiring harnesses to high-performance industrial equipment. The design of 6-cavity connectors often incorporates locking mechanisms that enhance stability and reduce the risk of accidental disconnections, further contributing to their reliability in automotive applications.

Understanding these characteristics is beneficial for engineers looking for the ideal connector for their system requirements. This ultimately leads to improved performance and longevity.

Simplifying Complex System Design

One of the advantages of using 6-cavity connectors is their ability to simplify the design of complex systems. By consolidating multiple connections into a single fitting, these connectors reduce the number of individual components required in a design.

This not only minimizes the potential points of failure but also streamlines the assembly process, making it easier for engineers to build and troubleshoot systems. The compact design of 6-cavity connectors allows for more efficient use of space within confined installations, which is particularly beneficial in automotive and aerospace applications where weight and space are essential parts of the process.

The standardization of these connectors across different system designs promotes interoperability, eases maintenance challenges, and enables engineers to replace or upgrade components quickly without extensive redesign. Essentially, 6-cavity connectors enhance reliability, contribute to a more efficient and manageable design process, and speed up project completion.

Facilitating Efficient Troubleshooting

Another notable advantage of using 6-cavity connectors in complex systems is their role in aiding troubleshooting within these systems. The consolidated nature of these connectors allows engineers to quickly identify and isolate problem areas.

Instead of dealing with numerous individual connections, technicians can focus on a single point, reducing the time spent diagnosing issues. This streamlined approach is particularly beneficial in the high-stakes environments of the automotive and aerospace sectors, where swift resolution can make a world of difference!

The clear organization of circuits within the connector improves clarity in wiring diagrams, making it easier for engineers to follow connections during maintenance or repair. With color-coded pins or physical keying, 6-cavity connectors enhance the user experience by reducing the risk of misconnection. These benefits contribute to increased uptime and reduced maintenance costs while ensuring complex systems can operate smoothly and efficiently.

Space-Saving Benefits of 6-Cavity Connectors

The compact design of 6-cavity connectors offers space-saving benefits, which are crucial in miniaturized electronics. By integrating multiple circuits into a single connector, these components reduce the amount of space the connections need between various devices.

This is particularly advantageous in automotive applications, where available space is limited and automakers need to take weight constraints into consideration. By minimizing the necessary number of connectors and wiring harnesses, engineers can create lightweight, efficient systems without sacrificing functionality.

The streamlined layout from the 6-cavity connectors not only improves the overall aesthetics of the installation but also promotes airflow and thermal management within confined spaces. This efficient use of space ultimately supports more innovative designs while guaranteeing systems remain easy to maintain and upgrade.

Enhancing Reliability and Durability

Reliability is an essential part of any engineering project. A single faulty connection can lead to system failures, costly repairs, and safety hazards. In automotive engineering, we can use 6-cavity connectors to provide secure, stable links.

Due to their durable construction, these connectors can withstand the harsh environments often encountered in automotive and industrial applications, from high temperatures to the idle shaking and rumbling of an active engine. Sturdiness translates to fewer maintenance issues and longer system lifespans, saving both time and money in the long run.

Improving System Performance

Utilizing 6-cavity connectors can improve the performance of complex systems. By supporting signal integrity through their high-quality construction, these connectors facilitate fast and reliable data transmission between components.

The well-designed contact configuration minimizes resistance and energy loss, allowing systems to operate efficiently under various loads. The ability to support multiple circuits within a single connector reduces the likelihood of electrical interference, which can be detrimental in high-speed applications.

As a result, engineers can improve responsiveness and functionality in their designs, contributing to enhanced system performance across automotive and industrial sectors. This performance boost not only elevates user experience but also ensures systems can meet the demands of modern technological advancements. By integrating 6-cavity connectors, engineers can create systems that function efficiently and adapt to future innovations.

Versatility in Applications

The versatility of 6-cavity connectors is one of their most noteworthy advantages, allowing technicians to employ them across a wide range of automotive systems, from automotive wiring harnesses to telecommunications systems. We design these connectors to support multiple electrical circuits in a single, compact unit, making them suitable for both high-performance and everyday use.

In the automotive sector, 6-cavity connectors facilitate the integration of various electronic components, including sensors, actuators, and infotainment systems. They support seamless communication and enhanced functionality.

Are you ready to elevate your engineering projects with reliable and efficient solutions? Look no further than Connector Experts for your 6-wire pigtail connector requirements!

We have a wide range of high-quality connectors that can simplify your designs, enhance performance, and save you valuable time and resources during assembly. Contact us today to learn more about how our connectors can work for your systems, or browse our online catalog to see if we have the right connectors for your needs. Reach out to us with any questions, comments, or concerns, and a member of our team will be happy to assist you.

You must login to post comments.