Comparing 3-Cavity Connectors to Other Connector Types

Comparing 3-Cavity Connectors to Other Connector Types

The intricate world of automotive technology relies heavily on robust connectors. These small components are crucial for ensuring seamless communication between different electrical systems. Connectors are vital in many modern automotive designs, Whether for power distribution, signal transmission, or data exchange. In this guide, we’ll compare three-cavity connectors to other connector types and discuss their unique features and advantages.

What Are Three-Cavity Connectors?

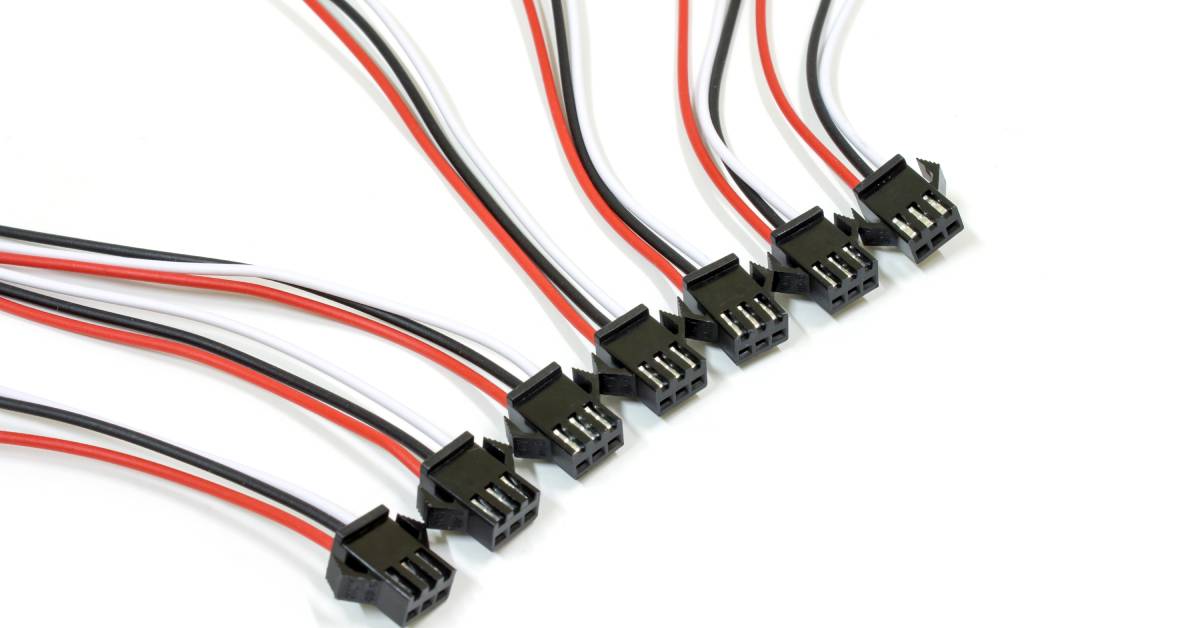

Three-cavity connectors are a specific type of connector designed to accommodate three distinct connections within a single housing. In the automotive industry, these connectors provide stable and secure connections between multiple electrical components. The design allows for efficient use of space while maintaining the integrity of each connection.

Additionally, three-pin connectors offer the advantage of streamlined installation and maintenance. Their design allows for easy integration into existing systems, and when replacing the existing component, the entire housing does not need to be replaced. This translates to cost and time savings for manufacturers.

Which Vehicles Use Three-Cavity Connectors?

Manufacturers can install three-cavity connectors in numerous vehicles, including cars, trucks, motorcycles, and off-road vehicles. Essentially, any vehicle designed with a three-pin connection system can benefit from using these connectors. This varies for vehicle make, model, year, and electrical system.

Comparing Types of Automotive Pin Connectors

Automotive connectors come in various types and configurations, each with its advantages and limitations. When choosing between pin connectors for automotive applications, it’s essential to consider factors such as the number of pins, as this impacts how many wires you can connect to it.

Three-Cavity vs. One-Cavity Connectors

One of the most significant differences between three-cavity connectors and their single-cavity counterparts is the number of connections they can accommodate. While one-cavity connectors may be suitable for simpler systems, three-cavity connectors offer greater versatility by allowing multiple connections within a single housing.

Three-Cavity vs. Eight-Cavity Connectors

Often, larger vehicles rely on eight-pin connectors to power various systems, while smaller vehicles can function with three-cavity connectors for the same system. For instance, a semi-truck may have an eight-cavity connector for its braking system, while a passenger car may only need a three-cavity connector for the same function.

As another example, a towing vehicle often requires larger connectors for areas such as exterior lights. This is because its connectors have to power the lighting, brakes, and other systems of the vehicle itself and its trailer in tow.

Comparing Shapes of Three-Cavity Connectors

Three-cavity connectors come in various shapes, including rectangular, square, triangular, and circular. Each shape offers unique advantages and may be more suitable for specific applications.

- Rectangular three-cavity connectors are popular for power distribution and data exchange due to their robust construction.

- Triangular three-cavity connectors offer enhanced flexibility and can easily accommodate multiple wire sizes.

- Circular three-cavity connectors are often used for signal transmission. They provide a secure connection while also allowing for easy insertion and removal.

- Square three-cavity connectors are standard for automotive applications due to their compact size and versatility.

Manufacturers must carefully consider their options and choose the right type of connector to maximize vehicle performance and reliability.

Pro Tip

If you have to buy automotive connectors and don’t know which shape to get, evaluate the existing connector. Turn it over in your hand to inspect it from all angles to determine the shape. This will help you find a compatible replacement and ensure seamless integration into your vehicle’s electrical system.

Comparing the Size of Three-Cavity Connectors

When comparing three-cavity connectors to other connector types, it’s also important to note the component’s size, as it can impact ease of installation and compatibility with existing systems. Generally, three-cavity connectors are smaller than connectors with more cavities, such as eight-pin connectors, making them a popular choice for compact automotive systems.

Typically, sedans and other compact vehicles utilize three-cavity connectors for their wiring in specific areas, while larger commercial vehicles may require connectors with more cavities. This is because sedans are smaller, so space for electrical components is limited, whereas larger vehicles have more room. Likewise, larger vehicles often have more complex and extensive electrical systems that require more connections due to the number of wires.

Three-Pin Connectors Versus Other Types of Connectors

Pin connectors are just one type of connector in the automotive industry. Other common types include blade connectors, spade connectors, and ring connectors. Each type has its own advantages and may be more suitable for certain applications depending on factors such as current-carrying capacity and environmental conditions.

Blade Connectors

These connectors, which have a flat, rectangular shape, are commonly used for power distribution applications. They offer high current-carrying capacity and can handle large amounts of power without overheating.

Spade Connectors

Spade connectors, also known as fork or U-shaped connectors, are typically used for connecting wires to screw terminals. They provide a secure and stable connection, making them ideal for automotive applications that involve vibration or movement.

Ring Connectors

Ring connectors have a circular shape with an opening that allows them to easily connect to bolts or screws. They are common in areas where connections need to be frequently changed or accessed for maintenance.

Why Choose Three-Pin Connectors

However, three-pin connectors offer several advantages, making them a popular choice for many manufacturers. These include their compact size, efficient use of space, and ease of installation and maintenance. Additionally, the ability to accommodate multiple connections within a single housing makes them highly versatile and suitable for various automotive applications.

Application Areas for Three-Cavity Connectors

As explained, three-cavity connectors excel in a variety of automotive applications, which can differ for various makes and models. Numerous vehicles rely on this connector for signal transmission applications because it can provide reliable performance under harsh conditions.

Likewise, three-pin connectors are commonly used for power distribution, particularly in compact vehicles where space is limited. A sedan may use three-cavity connectors for the engine control unit, sensors, and other electrical systems that require stable power distribution.

Tips for Buying Three-Cavity Connectors

As you shop for three-wire connectors, consider the following tips to ensure you choose the right components for your automotive needs:

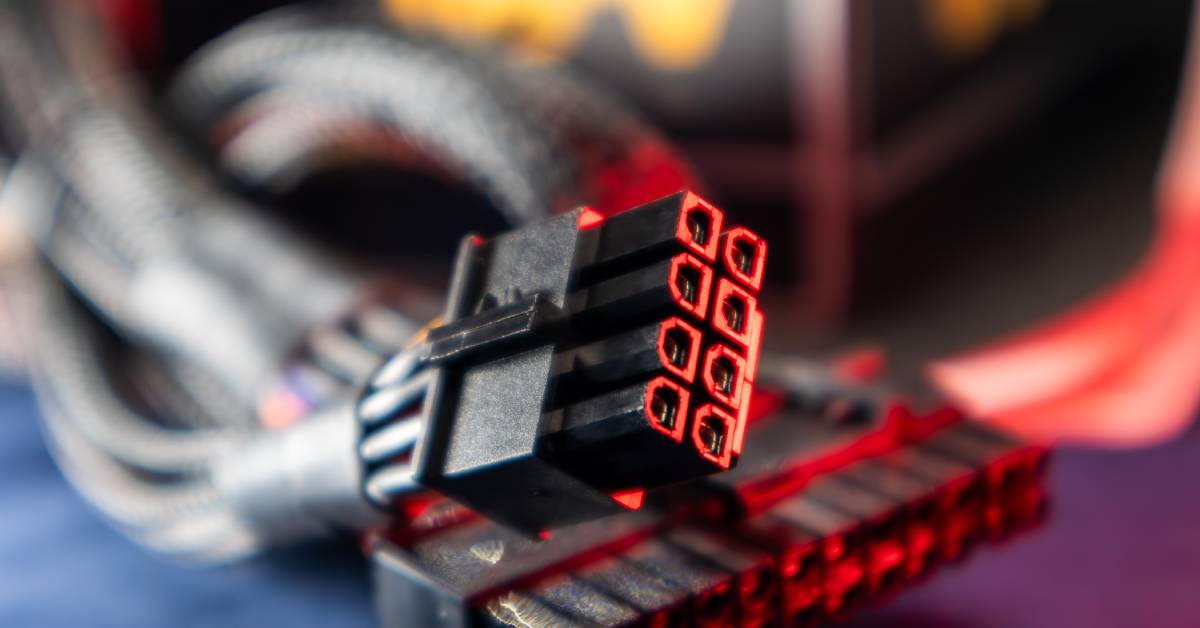

- Note the connector type; pin connectors feature a series of small metal pins arranged in a row or grid pattern.

- Count the number of pins and cavities needed based on your vehicle’s electrical system requirements.

- Consider the shape of the connector and whether it will be compatible with existing components in your vehicle.

- Evaluate the size of the connector and ensure it will fit in the designated area without hindering other components.

- Consider environmental factors such as temperature, moisture, and vibration to choose a connector with suitable protection levels.

Order Your Connectors

Connector Experts sell thousands of automotive connectors perfect for countless vehicle types, makes, and models. Shop our collection today to find the ideal replacement part to repair your electrical system.

You must login to post comments.