The Risks of Using Incompatible Electrical Connectors

Although all vehicles rely on electric connectors, not all connectors are the same. The use of incompatible electrical connectors can result in serious dangers, from electrical fires to damage to the vehicle. This can mean significant financial losses for manufacturers and potential consumer harm in the automotive industry.

This blog post explores the risks of using incompatible electrical connectors so you can ensure the safety and functionality of your vehicle’s electrical systems.

What Makes Connectors Incompatible?

Incompatibility can occur for a variety of reasons. For instance, connectors’ shapes, sizes, or pin layouts can differ, making it impossible for two connectors to work together. In addition, the materials they’re made of can vary, leading to different levels of durability and electrical conductivity.

Compatibility issues can also arise when you install connectors with voltage levels that are incompatible with the rest of your vehicle’s system. Connecting a higher-voltage connector to a lower-voltage system can lead to overheating, short circuits, and other electrical complications. On the other hand, using a low-voltage connector in a high-voltage system can result in malfunctions and damage to the vehicle’s electrical components.

Dangers of Incompatible Connectors

Using incompatible electrical connectors can lead to a wide range of dangers and complications:

Electric Shock

Electric shocks are major risks of using incompatible electrical connectors. Mismatched components can expose live electrical parts, increasing the risk of electric shock to users or maintenance personnel. Use connectors that fully enclose and protect live electrical parts to prevent these dangerous situations.

The Danger of Electric Shock

Electric shock is a serious hazard that can lead to injury or even death. People working with or near exposed live wires are at risk of receiving high-voltage shocks.

Electrical Shorts and Fires

Incompatible electrical connectors may fail to fit components, leading to poor contact or exposed wires. When connectors do not fit, they can create gaps that allow electrical currents to arc. Arcs can produce sparks that ignite surrounding materials and create fires.

Moreover, wires that are not securely enclosed within their connectors can easily come into contact with other wires or conductive surfaces. This can result in short circuits, intense heat, and sparks.

Overheating

Poor connections resulting from incompatible connectors can introduce high resistance points within an electrical circuit. High resistance points impede the flow of electrical currents, causing the energy to convert into heat. If electric components overheat in a car, there’s a major fire risk.

Non-Compliance With Standards

Using non-standard or incompatible connectors often violates automotive electrical codes and safety standards. Non-compliance with these standards can have serious legal repercussions, including fines and penalties.

Additionally, using incompatible connectors can void warranties on electrical equipment. Manufacturers specify the use of certain connectors to maintain the integrity and performance of their products. Deviating from these specifications can result in the manufacturer refusing to honor the warranty in case of equipment failure.

Pro Tip

While aftermarket goods may be cheaper, you should only use original equipment manufacturer (OEM). When producing OEM connectors for automotive wiring, manufacturers must follow strict safety and quality standards.

Damage to the Vehicle

If you install the wrong connector, it may provide too much or too little power. This is problematic because electrical systems operate best when all components receive the correct voltage and amperage.

Installing the incorrect connector may lead to excess current flowing through a component, causing it to overheat and burn out. Incompatible connectors can also cause voltage drops, reducing the efficiency of connected devices.

Why It Matters

Nearly all areas of a vehicle, from the engine control module to the headlights, rely on electrical circuits for operation. Damage to one of these circuits can result in poor performance or system failure.

Buy the Right Connectors

The risks of using incompatible connectors are too significant to ignore. Follow these tips to help you choose the right connectors for your vehicle:

Check Voltage Ratings

Before installing a connector, make sure its voltage rating matches the system it connects to. This ensures all electrical components receive the correct amount of power while reducing the risk of damage and malfunctions.

Review Current Connector Shape

Before making a purchase, review the shape of your current connector. Vehicles have different requirements, and connectors come in various shapes. Identifying the correct shape is the first step toward making a compatible purchase.

Look closely at your existing connector. Is it rectangular, circular, or another shape? One of the best ways to determine the exact shape is to look at the connector from all angles. Some shapes, such as rectangular and square, can look similar, while triangular connectors are easy to identify.

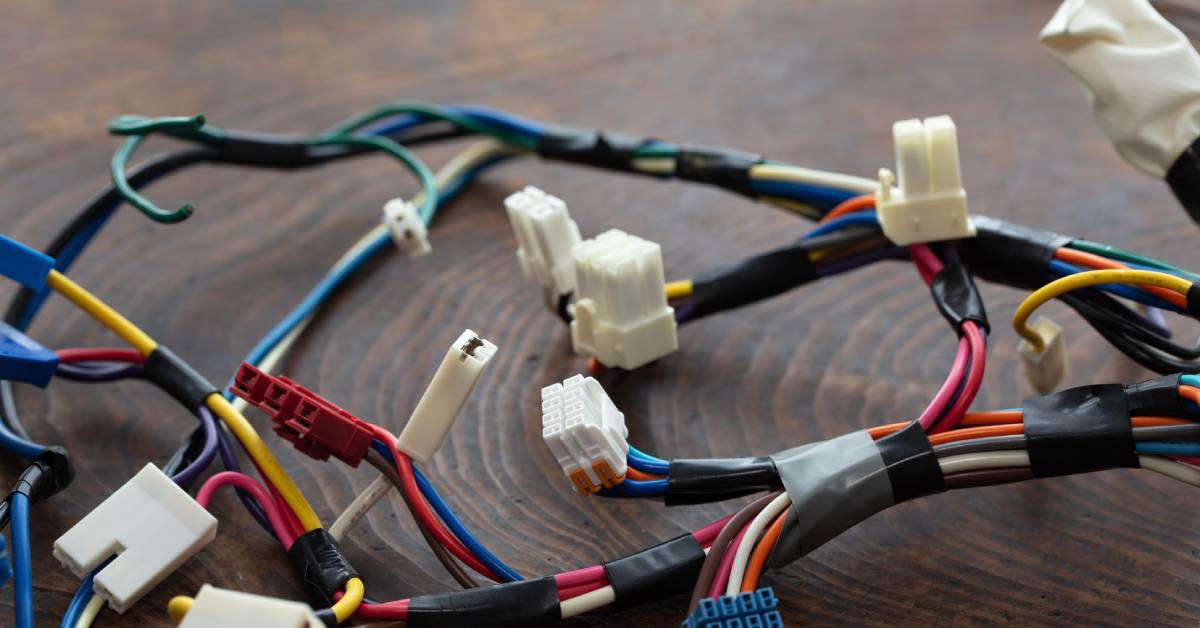

Count the Number of Pins

The number of pins varies depending on the connector type and functionality. Generally, small vehicles like sedans use connectors with few pins, while semi-trucks and forklifts require more pins to support more complex systems.

Once you remove the damaged connector from the vehicle, count the number of pins on the component. Take an accurate count, as misidentifying the number of pins can lead to ordering the wrong connector.

Although you can use a connector with more pins than wires, you should never use one with too few terminals. Each wire must connect to a pin, as it would otherwise be exposed and could create many dangers.

Read the Vehicle Manual

The manual contains vital information about the connectors approved for your vehicle and specifies the necessary connectors. Additionally, manuals often include diagrams of what the connectors look like—the shape and number of pins—which can be helpful if the current connector is damaged and unrecognizable.

Moreover, the manual will provide valuable information on the vehicle make, model, and year. You’ll need to buy a connector that matches these details and is for the same area of the car. For instance, if you need to replace the connector for the headlights in a 2020 Jeep Renegade, shop according to those details.

Consult a Professional

If you are still unsure about the correct connectors, contact the manufacturer you plan to buy the component from. They can provide guidance and recommendations for your vehicle’s electrical system. Automotive connector manufacturers have extensive knowledge of their products and can assist with compatibility concerns.

Shop at Connector Experts for Reliable Connectors

Connector Experts offers a wide selection of high-quality, reliable connectors for all types of vehicles. We manufacture our connectors in-house and follow all industry guidelines to produce OEM-equivalent connectors. Our team of experts is available to support and guide you in selecting the correct connectors for your vehicle’s electrical system.

You must login to post comments.