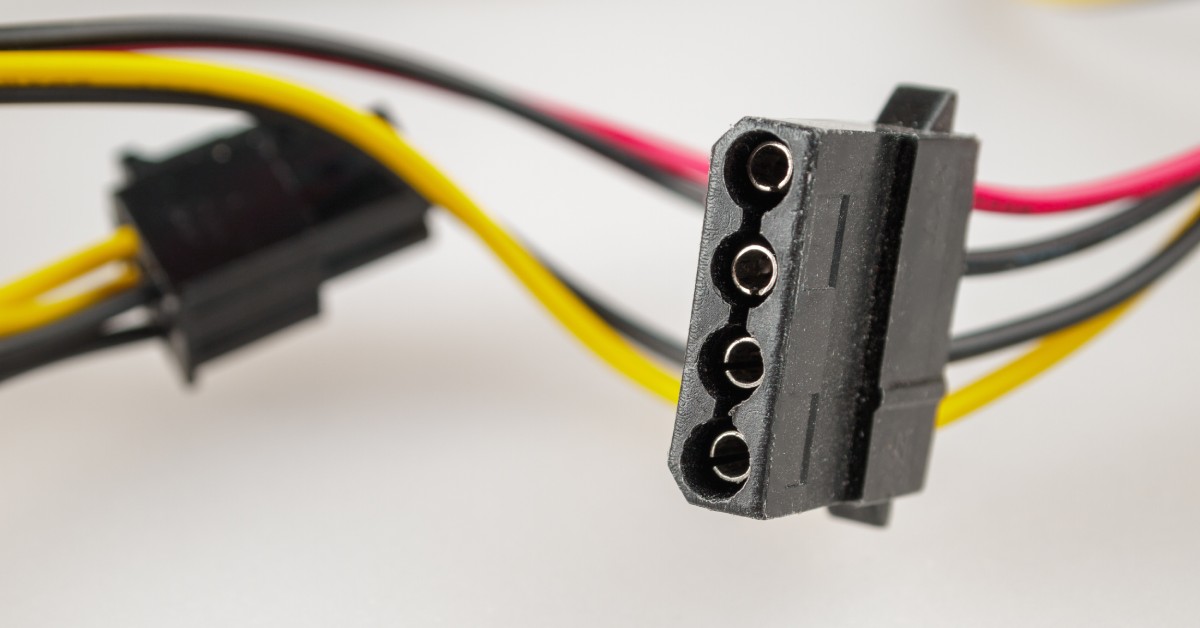

Common Issues With 4-Cavity Electrical Connectors

Electrical systems demand precision. A single faulty component can compromise an entire operation. You need your connections to be secure and reliable, especially when you work with multi-pin setups. This walkthrough will detail some of the common issues with 4-cavity electrical connectors so you can diagnose and solve them efficiently. Find out how to keep your connectors intact and reliable all year-round.

Corrosion: The Silent Threat

One of the most pervasive problems is corrosion. When metal contacts interact with moisture and oxygen, a chemical reaction occurs that degrades the material. This process creates resistance in the electrical path. The result is a weak or intermittent signal, which can cause erratic equipment behavior.

For example, a sensor on a piece of heavy machinery might send faulty data to the control unit. This could be due to corrosion on one of the connector's pins. The corrosion adds just enough resistance to alter the voltage, which leads to incorrect readings. The first step to a solution is to identify the source of moisture intrusion.

Seals and Environmental Protection

Your first line of defense is the connector's seals. High-quality 4-cavity connectors use silicone or rubber seals to create a barrier against dust and water. A compromised seal is an open invitation for contaminants. These seals can degrade from age, exposure to UV light, or contact with harsh chemicals like oils and solvents.

You must inspect seals during routine maintenance. Look for cracks, brittleness, or deformities. A seal that does not seat properly when you mate the connector is ineffective. If a seal has damage, it is best to replace the entire connector to guarantee a proper environmental barrier. This preventative action saves you from future electrical headaches. Don’t worry; you can always find replacement 4-pin connectors online that will help you keep your system running.

Galvanic Corrosion

Another form of corrosion to be aware of is galvanic corrosion. This happens when two dissimilar metals are in contact within an electrolyte, like saltwater. One metal will corrode at an accelerated rate compared to the other. In a connector, this can occur if the pins and sockets are made from different base metals or have incompatible plating.

Manufacturers select specific materials to prevent this. They use tin, nickel, or gold plating over copper alloy contacts. Problems arise when using an inferior quality connector, or when a connector is highly damaged and the base metal is fully exposed. Always use connectors from reputable sources that specify their material composition to avoid this complex issue.

Pin and Terminal Damage

The physical integrity of the connector’s pins and terminals is always important. Damage to these components can prevent a secure connection, which leads to immediate and obvious failures.

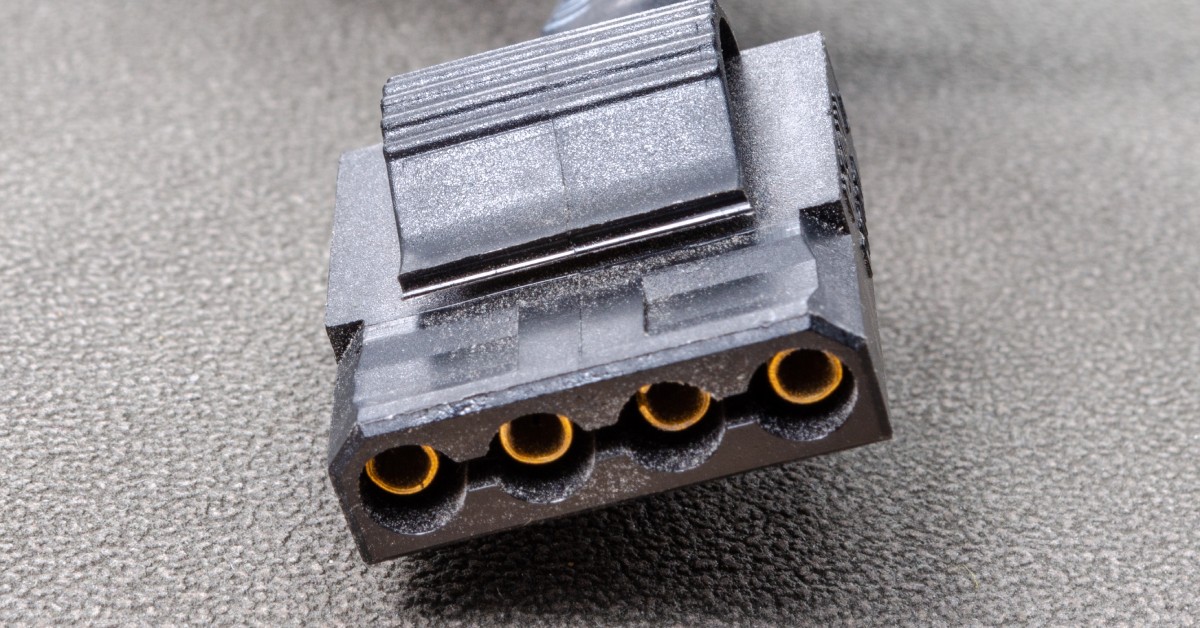

Bent or Broken Pins

Pins can bend during installation if they are not correctly aligned. A misaligned pin will not seat properly in its socket. It might even push the corresponding female terminal out of the back of the connector housing. A bent pin can sometimes be straightened with care, but a broken pin requires a full replacement of the connector or terminal.

Force is never the answer when mating connectors. They are designed to click together with minimal effort when aligned. If you meet resistance, stop and check the pin alignment. A quick visual inspection can prevent permanent damage that would halt your project.

Terminal Backout

Terminal backout is a frustrating and sometimes hard-to-diagnose issue. This occurs when a terminal is not fully seated in the connector cavity, or its locking feature fails. Vibrations from machinery or engine operation can cause the loose terminal to work its way backward, which breaks the electrical circuit.

The connection might test fine when the vehicle or machine is stationary. Once it starts to move, the intermittent failure appears. To prevent this, listen for the audible "click" when you insert a terminal into a connector cavity. You can also give a gentle tug on the wire to confirm the terminal is fully locked in place. This simple confirmation adds reliability to your build.

Wiring and Crimping Failures

The connection is only as good as the wire attached to it. Proper wiring and crimping techniques are always necessary for a dependable electrical system. Many connector failures are traced back to this fundamental step.

Improper Crimps

A bad crimp can create a host of problems. An under-crimp does not secure the wire tightly enough, which results in high resistance and a weak mechanical bond. The wire can pull out under tension. An over-crimp can be just as bad. It can crush the wire strands, weaken the conductor, and make it susceptible to breakage from vibration.

Use the correct crimp tool for the terminals you work with. Each terminal family has a designated tool that is engineered to apply the precise amount of force for a perfect crimp. Investing in the right tool pays for itself by eliminating a common point of failure. It turns a potential weakness into a source of strength.

Incorrect Wire Gauge

Using the wrong size wire for a terminal is another recipe for trouble. A wire that is too small will not crimp securely, which leads to the same issues as an under-crimp. A wire that is too large will not fit properly into the terminal barrel, which results in a compromised crimp and potential damage to the terminal itself.

Every terminal is rated for a specific range of wire gauges. This information is available on the manufacturer's datasheet. Cross-reference this information before you start your assembly. Taking a moment to verify the wire gauge will save you from intermittent faults down the line.

Overheating and Thermal Damage

When a 4-cavity connector begins to overheat, you have a serious problem. Heat is a byproduct of electrical resistance. Excessive heat can melt the connector housing, damage the insulation on the wires, and lead to a short circuit or even a fire.

Causes of Overheating

Overheating is almost always a symptom of another issue. A corroded terminal, a poor crimp, or a loose connection all increase resistance. As current flows through this high-resistance point, it generates heat. If the current draw is high, the temperature can rise rapidly to dangerous levels.

Another cause is overloading the circuit. If you attempt to run more current through a connector than it is rated for, it will overheat. The pins and wires are designed for a maximum amperage. Exceed that, and you push the components beyond their thermal limits. Always check the connector's current rating to ensure it is suitable for your application.

Identifying Overheating

You can spot an overheating connector by looking for discoloration or melting of the plastic housing. In some cases, you might smell burning plastic. If you find an overheated connector, it must be replaced. It is also crucial to identify and fix the root cause of the problem. This is where understanding the common issues with 4-cavity electrical connectors helps you build robust and reliable systems.

Solving these problems requires a systematic approach to assembly and diagnostics. Start with quality components, use the right tools, and follow best practices for every connection you make. Your systems will be safer and more dependable as a result.

You must login to post comments.