How Secondary Lock Systems Improve Connector Safety

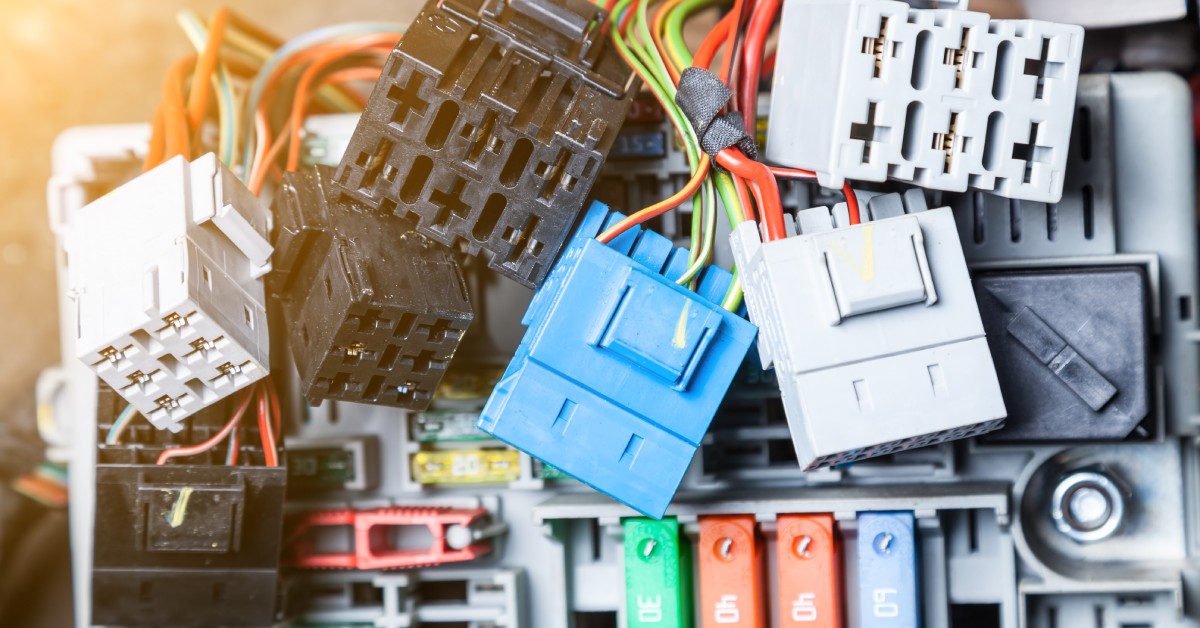

Electrical connections are the lifeline of modern machinery. You rely on them to keep critical systems running, from automotive engines to heavy industrial equipment. A single loose connector can cause catastrophic failure, downtime, or safety hazards.

That is why understanding how secondary lock systems improve connector safety matters for anyone managing high-performance hardware. Don't wait for a failure to happen; learn how high-quality locks will keep your systems in great condition.

The Reality of Connector Failure

Think about the environment where your equipment or vehicle operates. It’s likely not a quiet, still room. Engines vibrate, cars bounce over rough terrain, and industrial arms swing with force. These physical stresses constantly attack every component in the system.

Connectors feel this stress more than most parts. A standard latch might hold tight at first. Over time, vibration works against the plastic and metal mechanisms. The latch can fatigue or accidentally disengage if something strikes it.

When a connector comes apart, the circuit breaks. In a car, this might mean a sensor stops reading data, causing the engine to stall. In a factory, a robotic arm could lose power mid-cycle, dropping a heavy load. The consequences range from expensive repairs to dangerous accidents.

These failures are preventable. Relying on a basic primary latch is a gamble in high-vibration environments. You need a backup plan built directly into the hardware.

What Is a Secondary Lock?

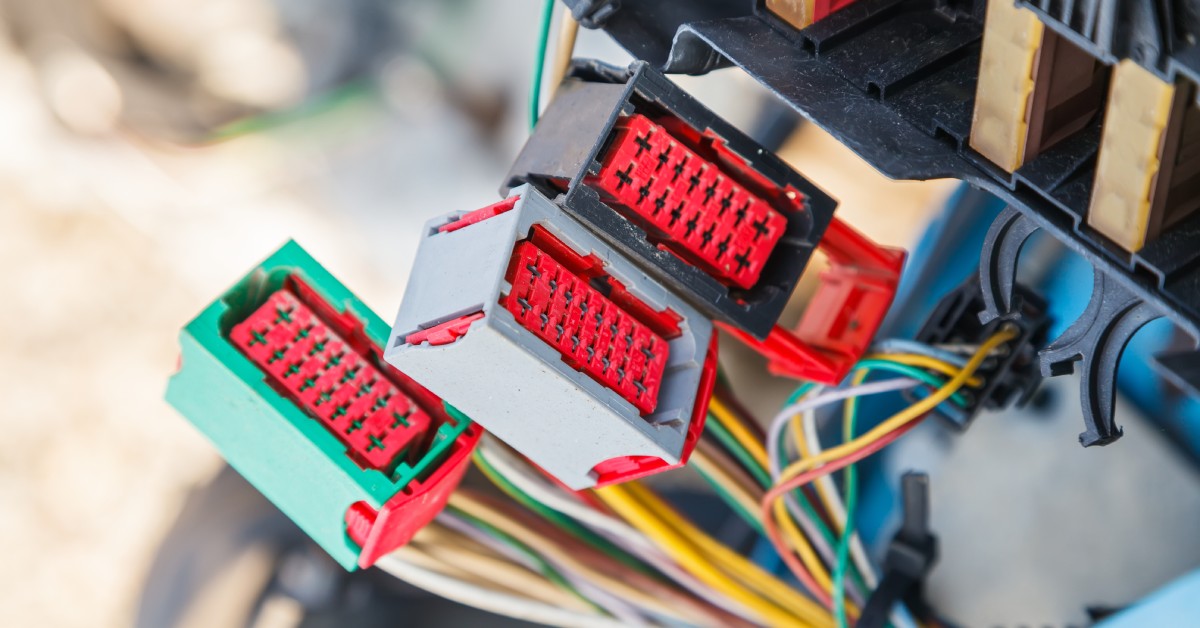

A secondary lock is an additional mechanism designed to secure a connector. Engineers call this a Terminal Position Assurance (TPA) or Connector Position Assurance (CPA) device, depending on its specific function. It acts as a fail-safe for the primary latch.

The primary latch does the heavy lifting of holding the connector halves together. It clicks into place when you mate the connectors. But primary latches rely on plastic flexibility, which can be a weak point under stress.

The secondary lock reinforces this connection. It is usually a separate piece of plastic that you slide or snap into place only after the connectors are fully mated. If the connectors aren't pushed together completely, the secondary lock won't engage.

This feature serves two purposes. First, it physically blocks the primary latch from releasing. Even if vibration shakes the connector or a stray wire snags the latch, the secondary lock keeps it closed. Second, it confirms that you mated the connectors correctly in the first place.

The Mechanics of Security

Let’s look at how these systems function mechanically. Imagine a standard automotive connector. You push the male and female ends together until you hear a click. That click is the primary latch engaging.

Now, you push a small tab on the back of the connector housing. This is the Connector Position Assurance (CPA). The tab slides under the primary latch arm. It fills the empty space that the latch needs to move downwards to release.

With that space filled, the latch cannot depress. It becomes mechanically impossible for the latch to disengage without first removing the secondary tab. The connector is now "locked" in a much more robust way than before.

Terminal Position Assurance (TPA) works slightly differently but offers similar protection. It locks the individual metal terminals inside the plastic housing. Sometimes terminals can back out of the housing if they aren't seated correctly. The TPA slides in to brace them from behind, preventing wire pull-out.

Preventing Human Error During Assembly

Once you buy a high-quality 2-wire pigtail connector online, you can rely on it to correctly mate to compatible components in your electrical system. However, human error can hinder the connector’s performance.

Assembly lines move fast. Technicians connect hundreds of plugs every shift. Fatigue sets in, and mistakes happen. A connector might look mated but hasn't actually latched.

This is a "false latch" scenario. The friction of the rubber seals holds the connector halves together temporarily. It passes a quick visual inspection. But as soon as the machine starts vibrating, the connection shakes loose.

Secondary locks act as a quality control check right on the line. Remember, the lock usually won't engage unless the connector is fully seated. If a technician tries to push the lock and it won't budge, they know immediately that the connection is incomplete.

This tactile feedback is invaluable. It forces the operator to stop and fix the problem before the unit moves to the next station. It eliminates the guesswork and drastically reduces the number of faulty connections leaving the factory.

Surviving High-Vibration Environments

Vibration is the enemy of electrical continuity. It causes "fretting," which is microscopic movement between metal contact points. This wears down the plating and causes corrosion, leading to intermittent signal loss.

Severe vibration can also unlock a standard latch. The constant shaking creates inertial forces that can momentarily depress the release tab. If that happens while tension is on the wire harness, the connector pops open.

Secondary lock systems add rigidity to the assembly. By filling the gaps in the latching mechanism, they reduce the amount of play between the connector halves. Less movement means less wear on the contacts and less chance of accidental decoupling.

Protection Against External Force

It’s not just vibration you have to worry about. Harnesses frequently run through tight spaces. During maintenance, a mechanic might reach past a bundle of wires to access a filter. Their arm could brush against a connector latch.

Without a secondary lock, that accidental bump could release the connector. The mechanic might not even notice. They finish their job, close the panel, and send the machine back out. A few hours later, the system fails because the plug worked its way loose.

A CPA prevents this scenario entirely. The latch is physically blocked from moving. Accidental pressure won't trigger a release. You have to intentionally disengage the secondary lock first.

This also protects against debris. In some environments, branches, rocks, or tools can strike exposed wiring. A robust locking system ensures that these random impacts don't result in electrical failure.

Securing Your Future

Every connection counts. From the smallest sensor to the main power feed, integrity is non-negotiable. You invest heavily in your technology; don't let a tiny plastic clip be the reason it fails. By implementing these robust locking mechanisms, you build resilience into your electrical systems. It is a simple engineering choice with a massive impact.

You now see how secondary lock systems improve connector safety and reliability. Take action to review your current designs. Identify where a standard latch leaves you vulnerable. Upgrade to connectors that offer the security your application demands.

You must login to post comments.