Why Terminal Tension Matters in Automotive Wiring

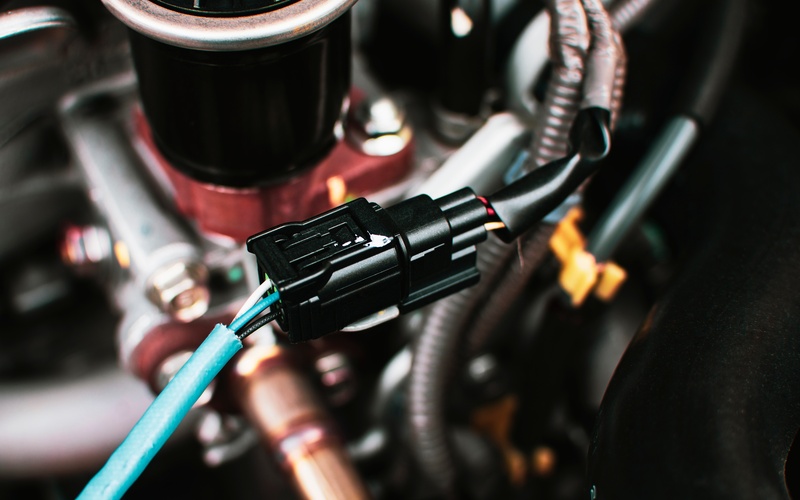

A vehicle's electrical system is a complex network. A series of wires connects countless components, from the engine control unit to the humble dome light. For everything to work correctly, every connection must be perfect.

This is where we need to discuss why terminal tension matters in automotive wiring. A secure connection goes beyond just a good crimp; it depends on the precise grip of the terminal itself. Let's explore this hidden force and what it means for your vehicle's health.

What Is Terminal Tension?

Think about plugging a cord into a wall outlet. You feel a slight resistance as the prongs slide into the socket. That resistance is a type of tension. It's the force that holds the plug securely in place, so it doesn't fall out.

In automotive wiring, terminal tension refers to the mechanical force a female terminal exerts on a male terminal pin or blade. It’s the "grip" that holds the two halves of a connector together. This force comes from the spring-like design of the female terminal, which is engineered to flex slightly as the male pin enters and then press firmly against it. This creates a stable, reliable electrical path.

Without adequate tension, connections become loose. This introduces a host of problems that can be incredibly frustrating to diagnose. The connection might seem fine visually, but electrically, it's a disaster waiting to happen.

The Physics of a Good Connection

A solid electrical connection needs two things: a clean metal-to-metal contact surface and sufficient pressure. Terminal tension provides that pressure. It squeezes the two conductive surfaces together, which overcomes any minor surface imperfections or thin layers of oxidation.

This force must be just right. Too little tension leads to a loose connection. Too much tension can damage the terminals or the connector housing during assembly or disconnection. It can even scrape away the protective plating on the terminals, which exposes the base metal to corrosion.

Intermittent Faults: The Gremlins in the Machine

A loose terminal is the perfect recipe for an intermittent electrical fault. These are the problems that appear and disappear without warning. One day, your radio cuts out on a bumpy road; the next day, it works perfectly. Your check engine light might come on for an hour and then vanish.

These maddening issues happen because a terminal with low tension can momentarily lose contact. A vibration from the engine, a bump in the road, or a change in temperature can be enough to shift the connection just enough to break the circuit. As soon as the vibration stops, the terminal might settle back into place, and the circuit works again.

Chasing these gremlins can consume hours of diagnostic time. A technician might check the wiring harness and find no visible damage. A continuity test might even pass if the meter's probe nudges the loose terminal back into contact. The root cause, low tension, remains hidden.

Voltage Drop and Its Consequences

Every electrical connection has some resistance. A good connection has very low resistance, so electricity flows through it with minimal loss. A connection with poor terminal tension has higher resistance.

This increased resistance causes a phenomenon called voltage drop. As electricity struggles to cross the loose connection, some of its energy dissipates as heat. This means the component at the end of the wire receives less voltage than it should.

A fuel pump that gets 11 volts instead of the required 13 volts will not perform as it should. It may run slower, which reduces fuel pressure and leads to poor engine performance. An ignition coil with low voltage will produce a weaker spark, which results in misfires and reduced fuel economy.

Heat, Corrosion, and Catastrophic Failure

You can buy wire harness connectors online right now, making repairs easy. However, there is still a lot to consider after the installation. The heat directly generated by a high-resistance connection is a serious problem. In a low-current circuit, like one for a sensor, the heat might be minor.

But in a high-current circuit, like for a radiator fan or a fuel pump, the heat can be substantial. This heat accelerates corrosion. It can melt the plastic connector housing and the wire's insulation. The exposed copper then oxidizes rapidly, which increases the resistance even more. This creates a vicious cycle: more resistance creates more heat, which creates more resistance.

Eventually, the connection can fail completely. The terminal may become so corroded that it no longer conducts electricity. In a worst-case scenario, the heat can become so intense that it starts a fire. A melted connector is a tell-tale sign of a connection that failed due to poor terminal tension.

How Terminals Lose Their Tension

Terminals don't stay perfect forever. Several factors can cause them to lose their grip over time. One common cause is constant connection and disconnection. Each cycle causes the female terminal to flex, and like any spring, it can weaken with repeated use.

This is why technicians use special tools to release terminals instead of just pulling on the wires. Another culprit is improper probing during diagnostics. Jamming an oversized test probe into a female terminal will permanently deform it. The delicate spring structure is bent open, and it will never grip the male pin tightly again. The only fix is to replace the damaged terminal.

Vibration and heat cycles also take their toll. Constant shaking can cause microscopic movements at the connection point, a process called fretting. This wears away the terminal's surface and reduces the contact pressure. Over time, the tension just fades away.

Protecting Your Vehicle's Electrical System

For the average car owner, the main takeaway is to treat your car's wiring with respect. Avoid pulling on wires to disconnect sensors. Never force a connector apart or together.

When you take your car for service, a good technician will understand these principles. They will know how to handle electrical connectors carefully. An expert will also diagnose problems by looking for the root cause, not just by replacing parts until the problem goes away.

This is where understanding why terminal tension matters in automotive wiring becomes a practical skill. Don't let intermittent electrical faults leave you stranded. If you suspect a wiring issue, bring your vehicle to professionals who appreciate the finer points of electrical repair.

You must login to post comments.