The Role of 7-Cavity Connectors in Automotive Electronics

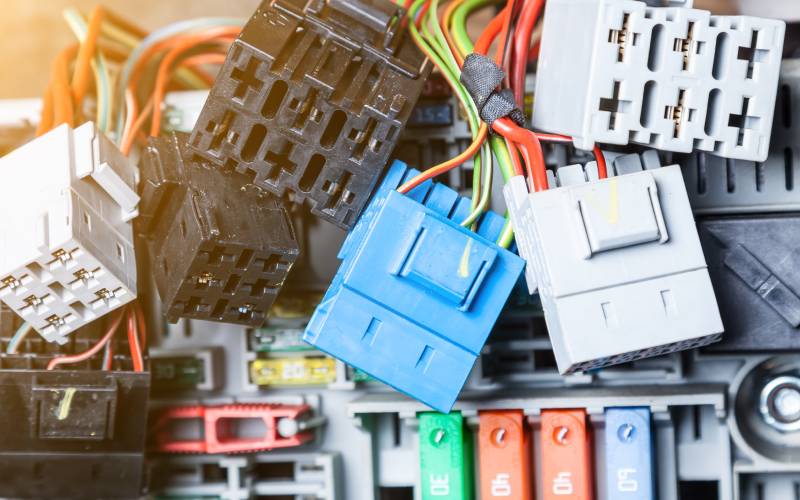

Engineers and designers are always looking for ways to improve communication between different automotive electronic components without sacrificing quality. Connectors need to maintain these stable connections, even in the face of environmental hazards. A lot goes into the role of 7-cavity connectors in automotive electronics and how their unique design and function keep things working. Connector Experts is here to go over these electronic components as well as their design, common applications, and general benefits.

What Are 7-Cavity Connectors?

A 7-cavity connector houses seven individual cables, one for each slot. Manufacturers engineer these connectors to establish a reliable connection between the different electronic components within a vehicle, such as the radio or headlights. This design guarantees that each terminal remains securely in place, preventing disconnections that could lead to system failures.

The use of 7-cavity connectors is not limited to one type of vehicle. They have various automotive applications, from passenger cars to commercial vehicles. The versatility of these connectors makes them indispensable in the automotive industry, ensuring that electronic systems function efficiently and reliably.

The Design and Structure of 7-Cavity Connectors

The design of 7-cavity connectors is a unique display of engineering precision. Designers have to craft each cavity to accommodate electrical terminals of specific sizes in order to minimize the risk of loose connections and make sure each terminal is snug. These connectors typically consist of durable materials, such as high-grade plastics or metals, that can withstand harsh automotive environments.

The structure of 7-cavity connectors includes locking mechanisms to secure the connection and prevent accidental disconnections. These connectors also come with seals to protect against moisture and dust ingress, enhancing their reliability and longevity. The combination of these design elements allows a 7-cavity connector to provide a stable and secure electrical connection in automobiles.

Applications in Automotive Electronics

Even when limiting it to the field of automotive electronics, 7-cavity connectors have a wide range of practical applications and abilities. One of their primary uses is in engine control units (ECUs), where they facilitate communication between the ECU and various sensors and actuators. This process guarantees that the engine operates efficiently and meets emission standards.

Another critical application is in lighting systems, where we can use 7-cavity connectors to connect headlights, taillights, and other lighting components. These connectors ensure that the lighting systems function reliably while enhancing vehicle safety. It’s also a common practice to install 7-cavity connectors in infotainment systems, where they connect audio, video, and navigation components to provide a seamless experience for the driver.

The Benefits of Using 7-Cavity Connectors

The role of 7-cavity connectors in automotive electronics offers several benefits. One of the primary advantages is their reliability. These connectors establish secure communication and minimize the risk of electrical failures, which is crucial for vehicle safety and performance. The design of 7-cavity connectors also allows for easy installation and maintenance, reducing downtime and associated costs.

Another significant benefit is the versatility of these connectors. They can accommodate different types of terminals, making them suitable for various applications within a vehicle. This simplifies the design and manufacturing process while reducing the need for multiple connectors. A 7-cavity connector can withstand extreme temperatures, vibrations, and environmental factors because it is made of strong materials.

Challenges and Considerations

While 7-cavity connectors offer numerous benefits, you should keep in mind that they also pose challenges. Compatibility with various electronic components is a big one. Designers need to confirm that the connector can fit into specific terminal sizes and configurations, which often vary between different vehicle manufacturers.

Another consideration is the cost. A high-quality 7-cavity connector generally costs more than standard connectors. However, many manufacturers justify the price with exceptional reliability and performance. Additionally, installing these connectors requires precision and attention to detail, which can incur high labor costs.

Future Trends in 7-Cavity Connector Technology

The future of 7-cavity connectors in automotive electronics looks promising, with ongoing advancements aimed at enhancing their performance and versatility. One of the emerging trends is the development of connectors with higher current-carrying capacity. This trend is a natural side effect of the increasing demand for high-power electronic systems in vehicles, such as electric and hybrid models, which rely heavily on electrical stability.

Another trend is the integration of smart features into electrical connectors. By designing connectors with built-in sensors to monitor the connection status and provide real-time feedback, vehicle owners can diagnose problems and fix them without issues or guesswork. This beneficial process can dramatically reduce the likelihood of system failures. General advancements in material science are leading to the development of connectors that are more resistant to environmental factors, further enhancing their reliability.

Best Practices for Implementing 7-Cavity Connectors

Implementing the best connectors in automotive electronics requires adherence to best practices for optimal performance and reliability. One such best practice is selecting connectors that meet the automotive industry standards and specifications. This supports compatibility with other components and guarantees that the connectors will perform as expected under various conditions.

Proper installation is another critical factor to consider. Manufacturers must correctly align and securely fasten the connections to minimize the risk of disconnections and electrical failures. They should also regularly inspect and maintain these connectors in order to stay on top of issues. Taking a proactive approach could prolong the lifespan of the connectors and prevent system failures.

In the ever-evolving landscape of automotive technology, creating reliable and high-performance connections is more critical than ever. At Connector Experts, we specialize in providing top-of-the-line connectors, including the versatile and durable 7-pin pigtail connector, to meet the diverse needs of automotive applications.

Whether you are upgrading an existing system or working on a new build, our connectors offer the reliability and quality you can trust. Check out our wide selection on our website to find the perfect connector for your automotive engineering needs. We offer far more than what you see on our site, so if you’re looking for something in particular, reach out to us anytime and we’ll see what we can do for you!

You must login to post comments.